For preparing plastic pipe samples for various tests by making a parallel cut and chamfering the finished edge. Typical tests requiring sample preparation are internal pressure, MCT, heat reversion, dimensions control and impact testing.

The solution offers a recipe system including features for pre-defined recipes, making it easy to get started no matter the material, length, thickness or diameter of the pipe.

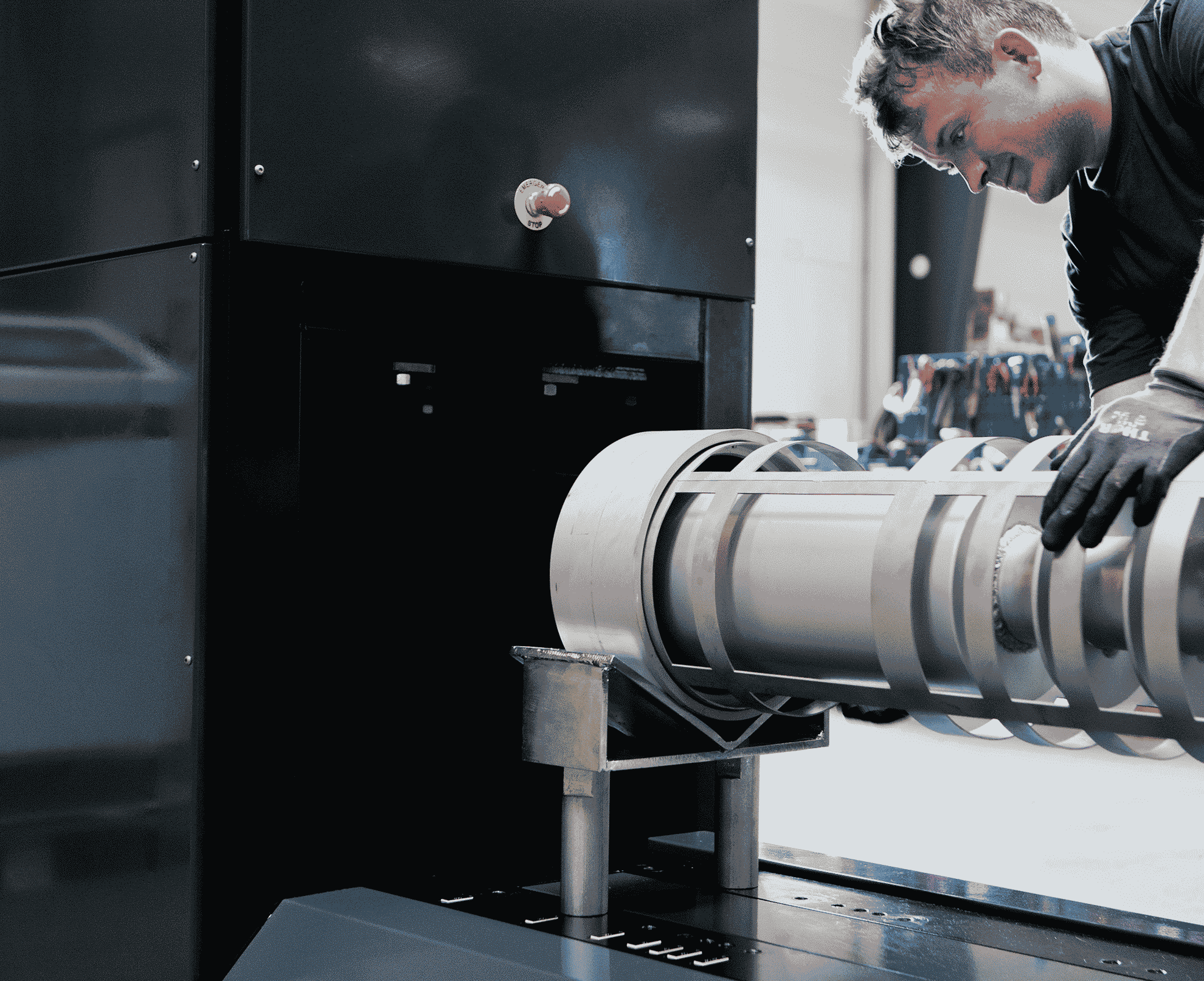

The pipe saw is specially designed for laboratory preparation of pipe samples for dimensions from Ø 50 mm up to Ø 800 mm as standard. The cutting of pipes is often made for internal pressure testing, impact tests, Glycerine, Methylene Chloride tests, dimension, dimension stability and other test purposes. In all the cases you need to cut and possibly chamfer the edge of the pipe.

Function

The SIGMA saw has adjustable underdrive rollers enabling cut of any pipe surface and diameter including corrugated pipes with nu use of extra tools.

The tower rollers are gas spring balanced for cutting out-of-round pipes. Tower rollers can be fitted with rotating edges or rubbers to eliminate longitudinal slipping of special pipe surfaces/materials. A surface follower is build-in to ensure smooth and uniform cutting and chamfering. The saw is controlled from the intuitive remote control included.

SIGMA software for intuitive and safe control

The touch screen enables safe remote control of the saw. The SIGMA software included offers easy and intuitive operation. The software includes a recipe system enabling accuracy in every cut, quick repetition of cuts, out-of-round compensation etc. The start screen allows you to make a new or choose an existing recipe. The recipe function enables quick setup of recipes via the recipe wizard guiding the operator step by step.

Operation from a safe distance

The saw is controlled from the touch screen and two-hand switch placed on a floor stand allowing the operator to initiate a cut from a safe distance. The chip guard shield is available as optional add-on as well as the chip/swarf exhaust is prepared for the optional vacuum separator bag.

Any type of surface or diameter

The underdrive rollers are individually adjustable to accommodate special combinations of pipe surface and diameters. The tower rollers are gas spring balanced ensuring a clean cut even on out-of-round pipes or pipe ovality. Also suitable for corrugated piping – no additional tools needed.

Easy handling of large dimensions

The conveyor table enables easy handling and feeding of the pipe to the cutter according to selected recipe. After the pipe is placed on the adjustable sledges and support rollers, the pipe is conveniently moved up to saw blade.

For more information and technical specifications please request a brochure below.

Associated equipment

Standards:

OD50 – 800mm / OD2 inch OD32 inch as standard.

5-70 mm - 3/16 inch to 2 3/4 inch.

PE, PP, PVC and similar. Smooth and corrugated pipe surfaces.

15°

Memory of up to 100 recipes.

+/- 1,5 mm

Pipe catcher (for cut offs/samples)

Exhaust swarf removal.

3x400 V + neutral, 50/60 HZ. or according to customer specifications.

L5617 x W1235 x H2525mm incl. standard conveyer.

Approx. 850 kgs. Depending on length of conveyer.

There are numerous international standards referring to testing. We supply testing equipment to fulfill any national and international testing standard within our field of business. In case you do not find the standard you are looking for in the below list, please contact us for further information

Standard test method for time-to-failure of plastic pipe under constant internal pressure.

Standard test method for resistance to short-time hydraulic failure pressure of plastic pipe, tubing, and fittings.

Standard test method for determination of the impact resistance of plastic pipe and fittings by means of a tup (falling weight).

Plastics piping and ducting systems - Thermoplastics pipes - Determination of resistance to external blows by the staircase method.

Plastics piping and ducting systems - Thermoplastics pipes - Test method for resistance to external blows by the round-the-clock-method.

Thermoplastics pipes, fittings and assemblies for the conveyance of fluids - Determination of the resistance to internal pressure Part 1: General method, Part 2: Preparation of pipe test pieces, Part 3: Preparation of components, Part 4: Preparation of assemblies.

‘The SCITEQ lab saw is running great. It has cut our sample prep time in half’.

View the full caseYour personal contact with us does not end with the commissioning of your test equipment. We also care about the operation of your solution.

We want to ensure optimal up-time based on preventive maintenance and efficient problem solving. You will achieve higher efficiency, high test reliability and a long life-time on your equipment.

We believe service is the key to a fruitful and long lasting cooperatio

Our services

We give you quality tools to produce as cost-effectively as possible, while meeting the highest standards. You will find it is possible to reduce time-to-market saving time on testing.

We help you configure future proof solutions. The SCITEQ equipment and cloud based software is developed by our in-house R&D engineers and manufactured in Europe.

We are close by. We perform global on-site installation as well as service visits and we are of course available for support and advice daily, so you can rest assured your test equipment will have maximum up-time.

The wide range of SCITEQ standard products is available for very short delivery. We will ship directly to your site to help you meet your deadlines. Need a special version? Not a problem, we love the challange.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).