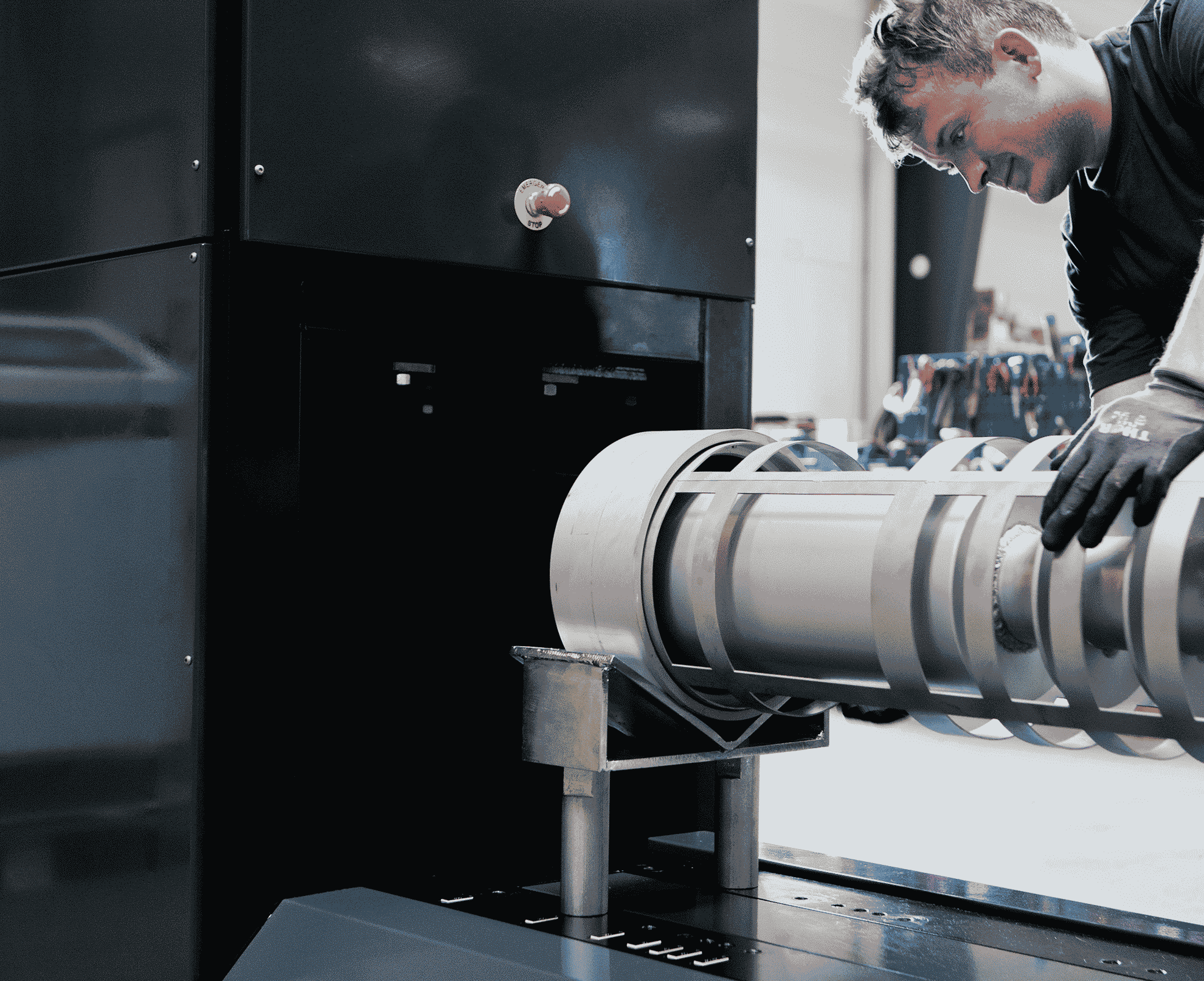

The SCITEQ Precision CNC Milling machine (computer-controlled) consists of a base frame with a linear movement milling top. Three axes (X, Y, Z) are available. The working area is 600 x 420 mm and the miller may prepare pipe samples with a wall thickness up to 110 mm.

The milling machine is ideal for preparing plastic pipe samples (‘dumbbell’ or ‘dog bone’ specimens) for e.g. tensile tests and other kinds of elongation tests. The CNC miller is supplied with pipe samples templates according to ISO 6259 types 1, 2 and 3. Other types on request.

Plug and play

A CNC controller (is part of the delivery and by means of software to be installed on a PC (PC not included), milling is performed. Further, software for engraving, cutting and drilling is included but not pre-programmed.

The spindle is equipped with a nozzle and pipe to remove the milling swarf/chips from the table. The CNC miller is supplied with pipe samples templates according to ISO 6259 types 1, 2 and 3. Other types on request.

A protection hood shields the operator and electromagnetic sensors ensure that the machine cannot be operated while the hood is open.

The system can be supplied with a vacuum device which removes the soft milling swarf into a storage bag. This can be retro-fitted if so desired.

For more information and technical specifications about the CNC milling machine please see the brochure.

Associated equipment

Wall thickness up to 120 mm.

Any plastics or composite material.

X: 600mm, Y: 420mm, Z: 280mm.

6-8 bar

- external suction device to remove swarf from cutting area templates

- additional pipe sample templates-other

- test standards besides ISO 6259.

- PC for milling software

Within 0,2 mm.

Within 1 mm.

1310 x 985 x 1070 mm (LxWxH)

Weight 380 kg.

There are numerous international standards referring to testing. We supply testing equipment to fulfill any national and international testing standard within our field of business. In case you do not find the standard you are looking for in the below list, please contact us for further information

Thermoplastics pipes - Determination of tensile properties.

‘The SCITEQ lab saw is running great. It has cut our sample prep time in half’.

View the full caseYour personal contact with us does not end with the commissioning of your test equipment. We also care about the operation of your solution.

We want to ensure optimal up-time based on preventive maintenance and efficient problem solving. You will achieve higher efficiency, high test reliability and a long life-time on your equipment.

We believe service is the key to a fruitful and long lasting cooperatio

Our services

We give you quality tools to produce as cost-effectively as possible, while meeting the highest standards. You will find it is possible to reduce time-to-market saving time on testing.

We help you configure future proof solutions. The SCITEQ equipment and cloud based software is developed by our in-house R&D engineers and manufactured in Europe.

We are close by. We perform global on-site installation as well as service visits and we are of course available for support and advice daily, so you can rest assured your test equipment will have maximum up-time.

The wide range of SCITEQ standard products is available for very short delivery. We will ship directly to your site to help you meet your deadlines. Need a special version? Not a problem, we love the challange.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).