SIGMA is the new generation of pressure testing helping our customers prepare for IoT and Industry 4.0. The intuitive interface enables easy operation when pressure testing plastic pipes and fittings in PE, PEX, PVC, PP, PB etc., glass fibre pipes, tubes and hoses.

SECURE REMOTE ACCESS

It is possible to update and service remotely via the internal Ethernet and/or external web access. The encrypted VPN and integrated firewall incl. in the site manager ensures a secure remote access.

COMPATIBILLITY

SQL database compatible with any server, enabling unlimited access and processing/use of test data. Data can be extracted by OPC UA .

PREDICTIVE MAINTENANCE

The SIGMA solution offers predictive maintenance system ensuring on-time maintenance and replacement of parts due to wear and tear. In case parts needs changing, this can easily be sourced via SCITEQ online spare part shop with individual customer login. Furthermore, the included self diagnostic system enables fast and easy troubleshooting in case of irregularities.

RECIPES

Recipes are quickly set-up, saving time when starting up a new test (diameter) as well as repeating saved test parameters. Up to four different user-levels from Basic to Advanced, ensuring not only easy operation, but also offering simultaneous ‘view-only’ access for your interested partners and clients.

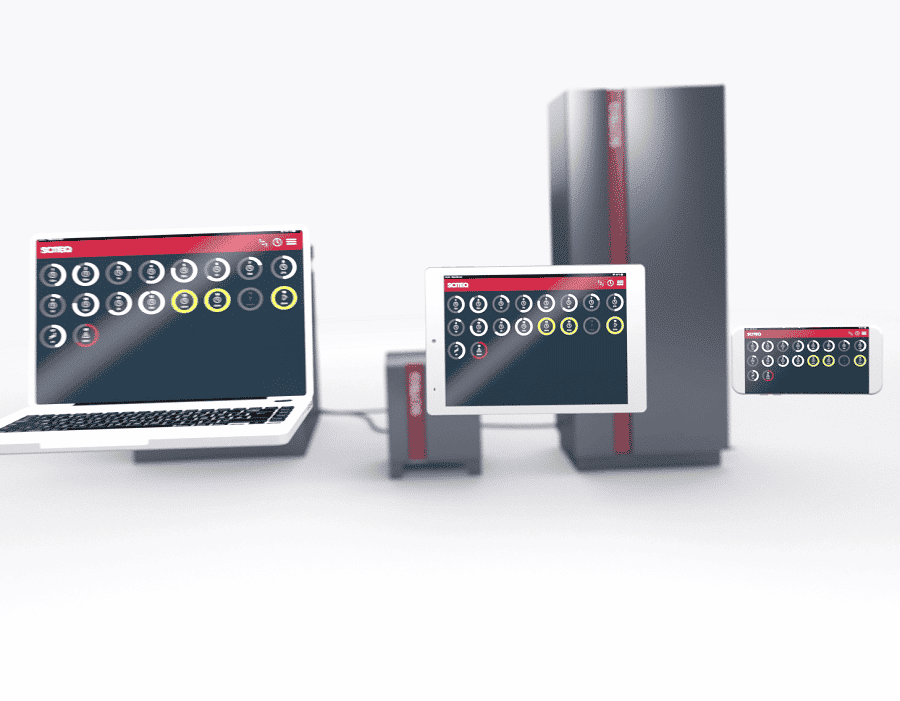

OPTIMIZED FOR TOUCH

The interface is optimized for touch, but can also be operated with mouse & keyboard. SCITEQ recommends the use of an iPAD pro 11” in shock and water proof cover. This is offered as option for SIGMA pressure installments.

For more information and specifications please see the SIGMA Software brochure.

THERMO TANK ASSIGNED STATIONS

SIGMA can be set up to only show the stations designated each thermo tank, meaning there will be a controller specifically set-up for each thermo tank only showing the stations assigned for this tank

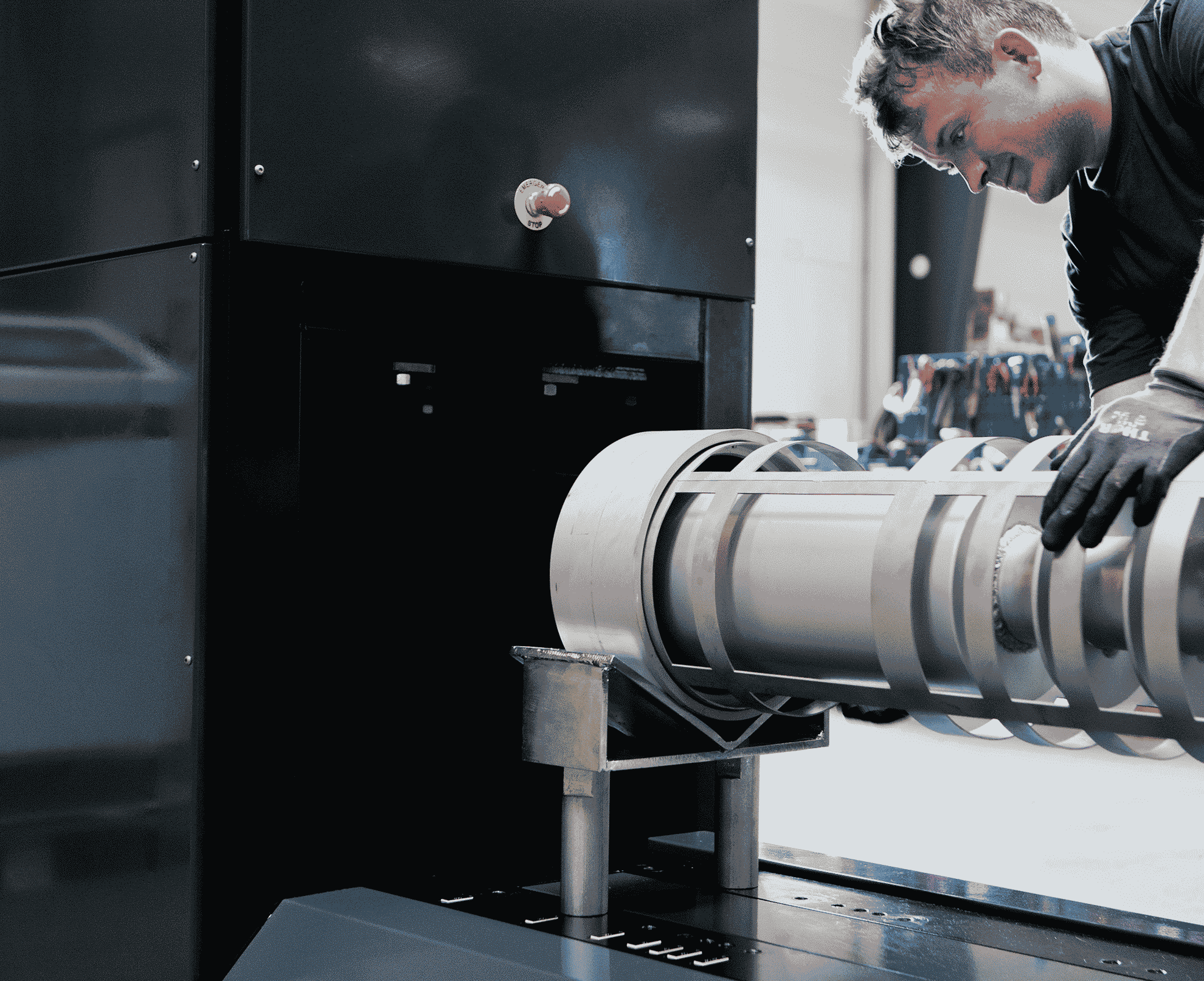

SIGMA pressure solution determines the resistance (both long term and short term) to internal pressure on thermoplastic pipes, fittings and assemblies for conveyance of fluids.

The product design complies with following pipe diameter configurations:

Up to Ø800 [mm] pipe diameter in long term test, provided the total volume expansion of the test specimen until pressure set point is reached is less than 120dm3 within 1 hour from test startup (max allowed pressuring time is 1 hour according to ISO1167 and max flow rate pr. SUB station is 2l/min)

Up to Ø315 [mm] pipe diameter in short term test, provided the total volume expanding until fracture (burst) is less than 10.5dm3 within 70 seconds from test startup (max allowed pressuring time is 70s according to ASTM D1599 and max flow rate in a BURST station is 9l/min)

The system consists of modular airless pressure modules designed to fit into an elegant standard cabinet with a compact footprint. The modularity enables easy configuration and extension of existing pressure cabinets, making SIGMA the most future proof and cost efficient solution in the market. System complies with the standards ISO 1167, EN 12 293 ASTM, D1598 and ASTM D 1599 and equivalent.

For more information on SIGMA pressure test equipment

Associated equipment

Standards:

There are numerous international standards referring to testing. We supply testing equipment to fulfill any national and international testing standard within our field of business. In case you do not find the standard you are looking for in the below list, please contact us for further information

Standard test method for time-to-failure of plastic pipe under constant internal pressure.

Standard test method for resistance to short-time hydraulic failure pressure of plastic pipe, tubing, and fittings.

Superseeded by EN 19893:2018 Plastics piping systems - Thermoplastics pipes and fittings for hot and cold water - Test method for the resistance of mounted assemblies to temperature cycling.

Thermoplastics pipes, fittings and assemblies for the conveyance of fluids - Determination of the resistance to internal pressure Part 1: General method, Part 2: Preparation of pipe test pieces, Part 3: Preparation of components, Part 4: Preparation of assemblies.

‘The SCITEQ lab saw is running great. It has cut our sample prep time in half’.

View the full caseYour personal contact with us does not end with the commissioning of your test equipment. We also care about the operation of your solution.

We want to ensure optimal up-time based on preventive maintenance and efficient problem solving. You will achieve higher efficiency, high test reliability and a long life-time on your equipment.

We believe service is the key to a fruitful and long lasting cooperatio

Our services

We give you quality tools to produce as cost-effectively as possible, while meeting the highest standards. You will find it is possible to reduce time-to-market saving time on testing.

We help you configure future proof solutions. The SCITEQ equipment and cloud based software is developed by our in-house R&D engineers and manufactured in Europe.

We are close by. We perform global on-site installation as well as service visits and we are of course available for support and advice daily, so you can rest assured your test equipment will have maximum up-time.

The wide range of SCITEQ standard products is available for very short delivery. We will ship directly to your site to help you meet your deadlines. Need a special version? Not a problem, we love the challange.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).