The Point load tester system complies with the standard PAS 1075:2009 Annex A3. PAS 1075 defines characteristics, requirements and test methods for pipes made of PE for alternative installation procedures.

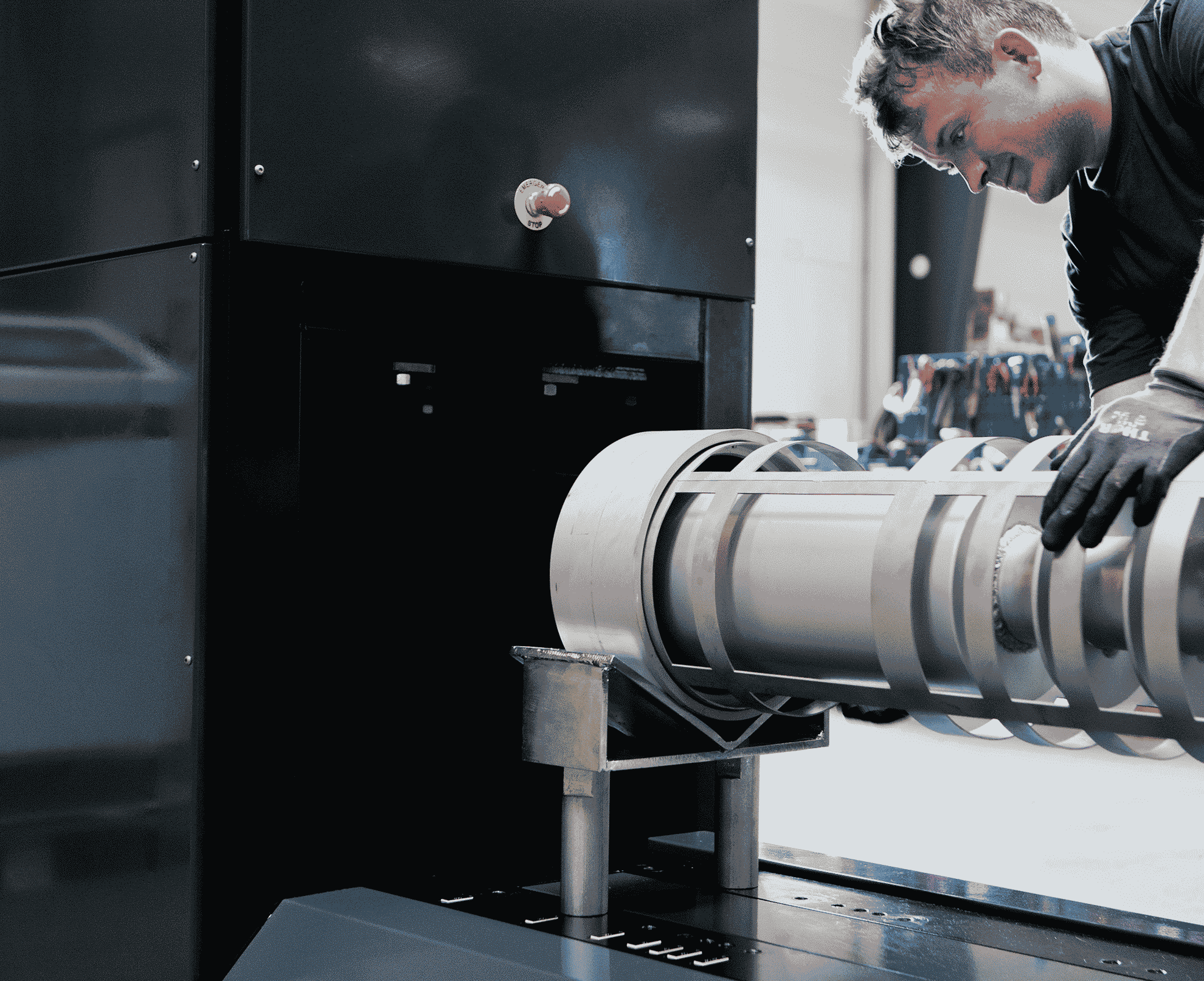

The Point load tester system consists of three main parts, namely the PLT pressure station cabinet, the PLT thermo tank and the PLT frames with the circular 4-screw point load testing unit and end closures.

A pipe sample mounted with end closures is placed in the open PLT frame where the pipe sample rests on the frame. Subsequently the PLT unit is mounted on the frame and the four PLT screws are fixed on the pipe sample and adjusted. The PLT frame is ready to be emerged into the thermo tank where the pipe sample can be aired out and pressurized.

For more information and technical specifications please see the brochure.

Associated equipment

Ø16mm up to Ø630mm (other sizes on request).

for instance detergent solution.

pressure station controller.

thermo tank with heating capacity and control up to 95°C.

3x400Vac, 50Hz, 1kVA, single phase 3 wires.

depending on pipe dimension and requirements.

individual circulation pump for each pipe sample.

flow 1.33 l/min in pipe samples, magnetic drive.

four screw inserts (other no. on request).

220/230V.

4 to 8 bar.

dependant on model.

There are numerous international standards referring to testing. We supply testing equipment to fulfill any national and international testing standard within our field of business. In case you do not find the standard you are looking for in the below list, please contact us for further information

For determining the resistance to slow crack growth of polyethylene pipes with external point load (Annex A3).

‘The SCITEQ lab saw is running great. It has cut our sample prep time in half’.

View the full caseYour personal contact with us does not end with the commissioning of your test equipment. We also care about the operation of your solution.

We want to ensure optimal up-time based on preventive maintenance and efficient problem solving. You will achieve higher efficiency, high test reliability and a long life-time on your equipment.

We believe service is the key to a fruitful and long lasting cooperatio

Our services

We give you quality tools to produce as cost-effectively as possible, while meeting the highest standards. You will find it is possible to reduce time-to-market saving time on testing.

We help you configure future proof solutions. The SCITEQ equipment and cloud based software is developed by our in-house R&D engineers and manufactured in Europe.

We are close by. We perform global on-site installation as well as service visits and we are of course available for support and advice daily, so you can rest assured your test equipment will have maximum up-time.

The wide range of SCITEQ standard products is available for very short delivery. We will ship directly to your site to help you meet your deadlines. Need a special version? Not a problem, we love the challange.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).