SCITEQ SIGMA pressure solution determines the resistance (both long term and short term) to internal pressure on thermoplastic pipes, fittings and assemblies for conveyance of fluids,

complying with following test standards and equivalent:

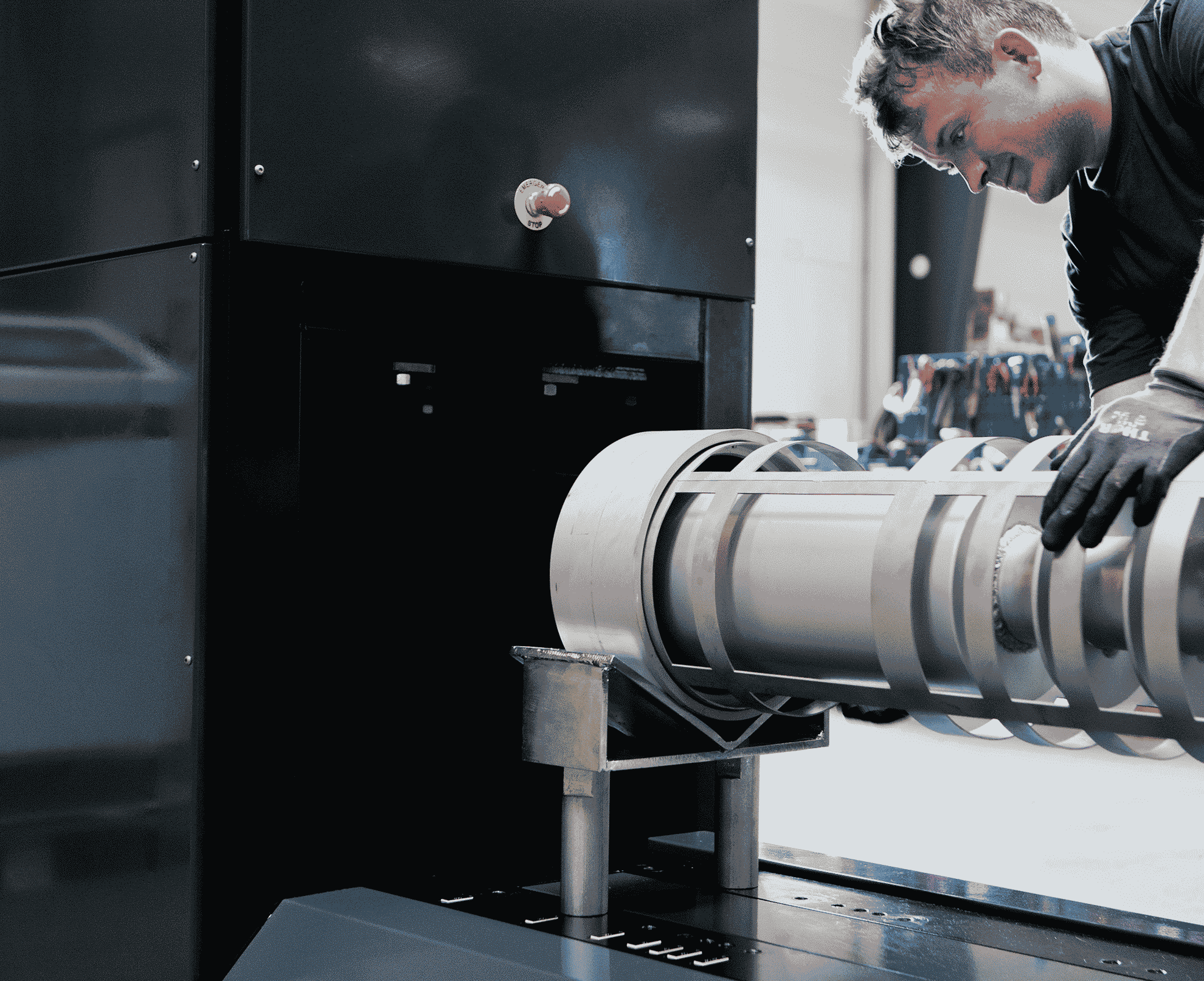

SIGMA PowerPack module

Pressure source feed to all SUB (pressure) modules with 5 or 10 pressure outlets. The pressure outlets are seamlessly performing static, step and burst testing used for both R&D purpose and batch release testing. Various models available incl./excl. output for optional BURST modules. With built-in high pressure pump and 10 micron inlet filter.

SIGMA SUB module

Provides 5 or 10 independently operating pressure stations up to max. 100 or 160 bar. Semi-automatic individual pressure transmitter calibration through integrated main transmitter is optional. Built-in fast reacting valves for precise pressure control.

SIGMA BURST module

Provides one linear burst pressure station up to max. 200bar within 60-70 seconds. Built-in fast reacting high flow and pressure valves for fast and precise pressure control. Requires PowerPack module with output for BURST module.

SIGMA HCP3 module

Provides three independently high volume operating pressure stations up to max. 100bar regulated pressure output. Built-in fast reacting valves for precise pressure control.

DPCS – Dynamic Pressure Control System

SCITEQ’s intelligent Dynamic Pressure Control System ensures that test pressures are maintained with unparalleled accuracy no matter what size sample is connected to the system. Static, burst and step testing can all be accommodated.

Flow per station: max. flow 2 l/min (max. flow 15 l/min for burst). For other valve flow and power pack flow configurations, refer to the SCITEQ HCP solutions.

The built-in alarm light instantly alerts the operator visually in case of irregularities in the ongoing test.

The browser-based SIGMA software is accessible from any device – any time, anywhere. The advantages are among others:

The fast and extremely easy to use interface enables easy operation and control of few as well as many simultaneous pressures tests with features such as dynamically adjusted finish time, full station overview and click less maneuvering.

Recipes are quickly set-up, saving time when starting up a new test (diameter) as well as repeating saved test parameters. Up to four different user-levels from Basic to Advanced, ensuring not only easy operation, but also offering simultaneous ‘view-only’ access for your interested partners and clients.

For more information and technical specifications about the SIGMA pipe pressure test please go to SIGMA software or check the brochure below.

SIGMAlite is the compact plug and play test unit with five fixed individual pressure stations ideal for smaller layouts. Incl. DPC system and ABX valves ensures consistent and unparalleled pressure accuracy.

Associated equipment

Up to 100 or 160 bar regulated pressure output

Up to 200 bar unregulated output (burst)

Max. flow 2 l/min (max. flow 15 l/min for burst)

40 pressure stations (up to 60 stations on request)

3 phase 380-400Vac + N + PE, 16amps

mains water supply, 2-6 bar

lead to gravity fed waste water

CAB5 - up to 40 stations: 794x800x1880mm (LxWxH)

CAB6 - up to 50 stations: 794x800x2100mm (LxWxH)

Depends on no. of pressure stations, approx. 400 kgs

There are numerous international standards referring to testing. We supply testing equipment to fulfill any national and international testing standard within our field of business. In case you do not find the standard you are looking for in the below list, please contact us for further information

Standard test method for time-to-failure of plastic pipe under constant internal pressure.

Standard test method for resistance to short-time hydraulic failure pressure of plastic pipe, tubing, and fittings.

Plastics piping systems - Thermoplastics pipes and fittings for hot and cold water - Test method for the resistance of mounted assemblies to temperature cycling.

Thermoplastics pipes, fittings and assemblies for the conveyance of fluids - Determination of the resistance to internal pressure Part 1: General method, Part 2: Preparation of pipe test pieces, Part 3: Preparation of components, Part 4: Preparation of assemblies.

‘The SCITEQ lab saw is running great. It has cut our sample prep time in half’.

View the full caseYour personal contact with us does not end with the commissioning of your test equipment. We also care about the operation of your solution.

We want to ensure optimal up-time based on preventive maintenance and efficient problem solving. You will achieve higher efficiency, high test reliability and a long life-time on your equipment.

We believe service is the key to a fruitful and long lasting cooperatio

Our services

We give you quality tools to produce as cost-effectively as possible, while meeting the highest standards. You will find it is possible to reduce time-to-market saving time on testing.

We help you configure future proof solutions. The SCITEQ equipment and cloud based software is developed by our in-house R&D engineers and manufactured in Europe.

We are close by. We perform global on-site installation as well as service visits and we are of course available for support and advice daily, so you can rest assured your test equipment will have maximum up-time.

The wide range of SCITEQ standard products is available for very short delivery. We will ship directly to your site to help you meet your deadlines. Need a special version? Not a problem, we love the challange.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).