SCITEQ ECO line thermo test tanks are primarily used for immersing pipe samples in water at a accurately controlled temperature, during hydrostatic pressure test, but also for conditioning of any type of sample that requires controlled temperature immersion. The tanks are suitable for testing according to ISO 1167, ASTM D1598 and ASTM D1599

Low energy consumption

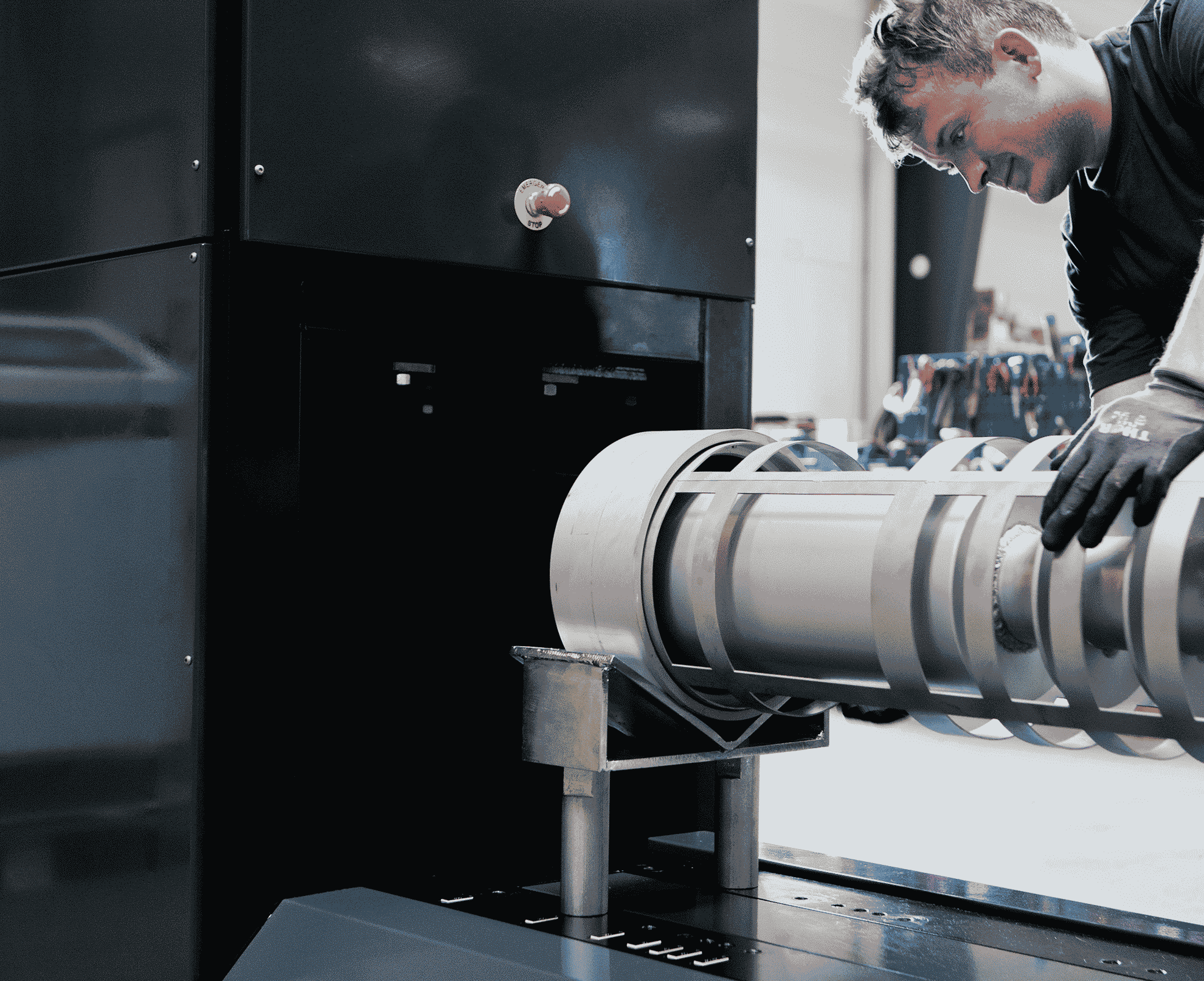

An inner tank in stainless steel (Aisi 316 and others on request). The compact thermal insulation in the thermo tank reduces heat loss and eliminates the risk of hot outer surfaces. Combined with the innovative heating elements and heating circulation pumps, temperatures inside the thermo tanks are both constant and uniform.

Easy access

The design focuses on intuitive & ergonomic use and cost efficient construction. The tank consists of an outer heavy duty frame in painted steel with easy removable cover plates. With the smart safety lid easily and safely operated by pneumatic cylinders, you can easily access the tank from all three sides. In the case of a power failure, the lid will stay in position. The design also allows for easy maintenance; heating elements, pumps, valves and temperature sensors can all be removed without the need to drain the tank of water.

For more information and technical specifications please see the brochure.

Associated equipment

Standards:

19-95° Celcius

from 1500x1000x1300mm to 3500x1850x1850 mm (LxWxH). Volume range of 1,71 -12 m3 water.

1/8" male connection and supplied with screw operated bleed valve.

up to 100 bar (depending on standard, specifications and pipe sample diameter)

There are numerous international standards referring to testing. We supply testing equipment to fulfill any national and international testing standard within our field of business. In case you do not find the standard you are looking for in the below list, please contact us for further information

Standard test method for time-to-failure of plastic pipe under constant internal pressure.

Standard test method for resistance to short-time hydraulic failure pressure of plastic pipe, tubing, and fittings.

Thermoplastics pipes, fittings and assemblies for the conveyance of fluids - Determination of the resistance to internal pressure Part 1: General method, Part 2: Preparation of pipe test pieces, Part 3: Preparation of components, Part 4: Preparation of assemblies.

‘The SCITEQ lab saw is running great. It has cut our sample prep time in half’.

View the full caseYour personal contact with us does not end with the commissioning of your test equipment. We also care about the operation of your solution.

We want to ensure optimal up-time based on preventive maintenance and efficient problem solving. You will achieve higher efficiency, high test reliability and a long life-time on your equipment.

We believe service is the key to a fruitful and long lasting cooperatio

Our services

We give you quality tools to produce as cost-effectively as possible, while meeting the highest standards. You will find it is possible to reduce time-to-market saving time on testing.

We help you configure future proof solutions. The SCITEQ equipment and cloud based software is developed by our in-house R&D engineers and manufactured in Europe.

We are close by. We perform global on-site installation as well as service visits and we are of course available for support and advice daily, so you can rest assured your test equipment will have maximum up-time.

The wide range of SCITEQ standard products is available for very short delivery. We will ship directly to your site to help you meet your deadlines. Need a special version? Not a problem, we love the challange.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).