The unit is produced as a model for outside marking of samples, with a distance between the pins of 100mm, and alternatively with 3 pins, each with 100 mm between the pins, to ensure higher measuring accuracy. The standard model covers pipes with OD Ø40mm to Ø630mm.

The unit is also produced as one to make markings on the inside diameter of pipes. This unit is especially intended for corrugated and Rib/Ultrarib pipes where an outside marking is not possible.

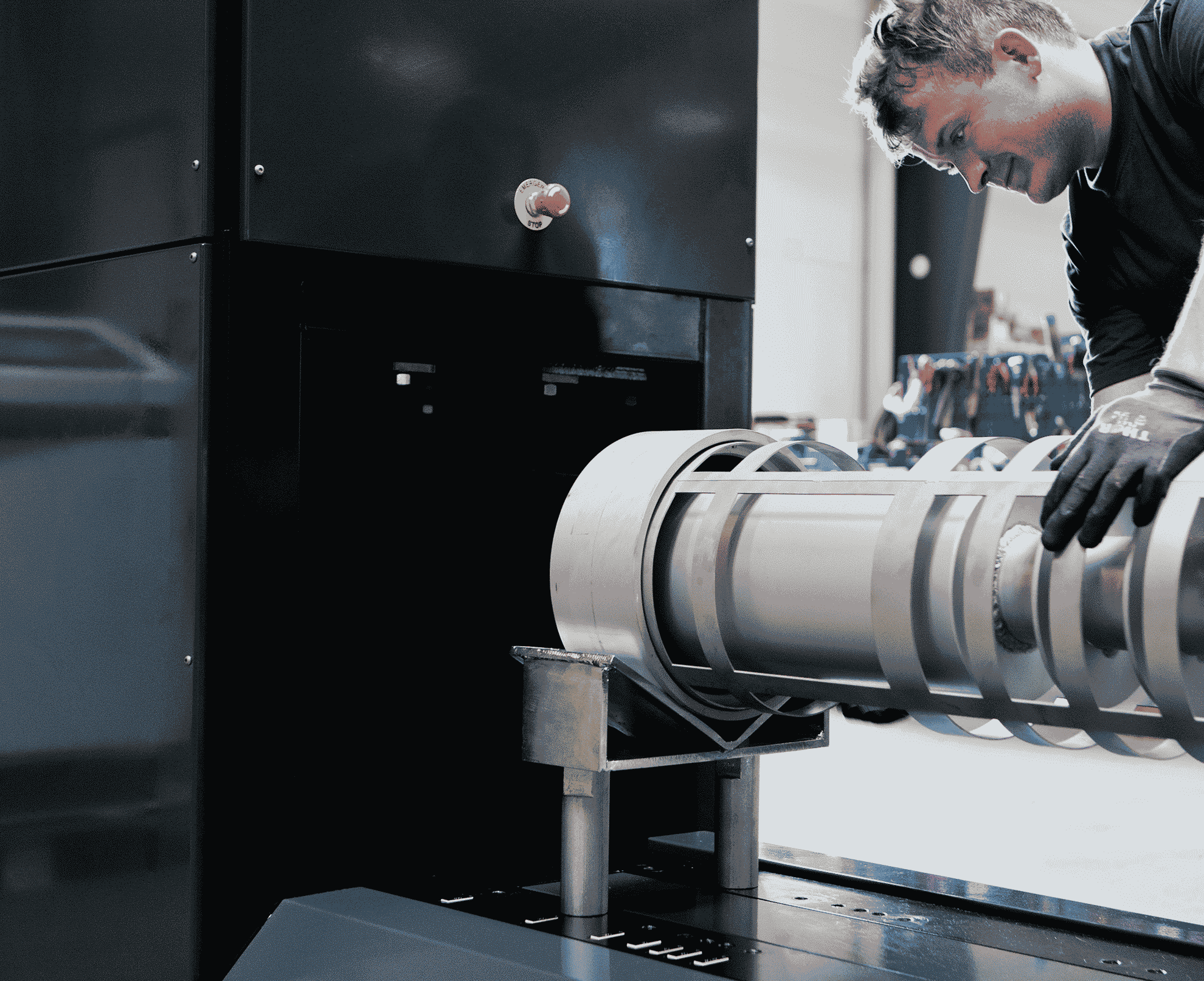

The pipe sample is cut in a length to perform the parallel markings. Thereafter it is placed on the Vblock against the stop rollers. A contra weight on the marking pins makes sure that the sample is cut deep enough for clear visible markings, while rotating the sample manually on the V-block. SCITEQ also produces a portable parallel scratchier. The unit is produced as a model for outside marking of samples, with a distance between the pins of 100mm. The unit can be used on pipes with an outside diameter from 200mm and larger.

For more information and technical specifications about our parallel scratchier please see the brochure.

Associated equipment

100 mm.

Ø40 mm - Ø630 mm.

300 x 300 x 260 mm. (LxWxH)

12 kg.

There are numerous international standards referring to testing. We supply testing equipment to fulfill any national and international testing standard within our field of business. In case you do not find the standard you are looking for in the below list, please contact us for further information

Methods of testing - Plastics - Introduction.

Plastics piping and ducting systems- Thermoplastics pipes; Determination of the longitudinal reversion.

Thermoplastics pipes - Longitudinal reversion - Test method and parameters.

Polyethylene pipes (PE) - Longitudinal reversion - Test methods and specification.

Polypropylene (PP) pipes - Determination of longitudinal reversion.

Thermoplastics pipes - Determination of tensile properties.

‘The SCITEQ lab saw is running great. It has cut our sample prep time in half’.

View the full caseYour personal contact with us does not end with the commissioning of your test equipment. We also care about the operation of your solution.

We want to ensure optimal up-time based on preventive maintenance and efficient problem solving. You will achieve higher efficiency, high test reliability and a long life-time on your equipment.

We believe service is the key to a fruitful and long lasting cooperatio

Our services

We give you quality tools to produce as cost-effectively as possible, while meeting the highest standards. You will find it is possible to reduce time-to-market saving time on testing.

We help you configure future proof solutions. The SCITEQ equipment and cloud based software is developed by our in-house R&D engineers and manufactured in Europe.

We are close by. We perform global on-site installation as well as service visits and we are of course available for support and advice daily, so you can rest assured your test equipment will have maximum up-time.

The wide range of SCITEQ standard products is available for very short delivery. We will ship directly to your site to help you meet your deadlines. Need a special version? Not a problem, we love the challange.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).