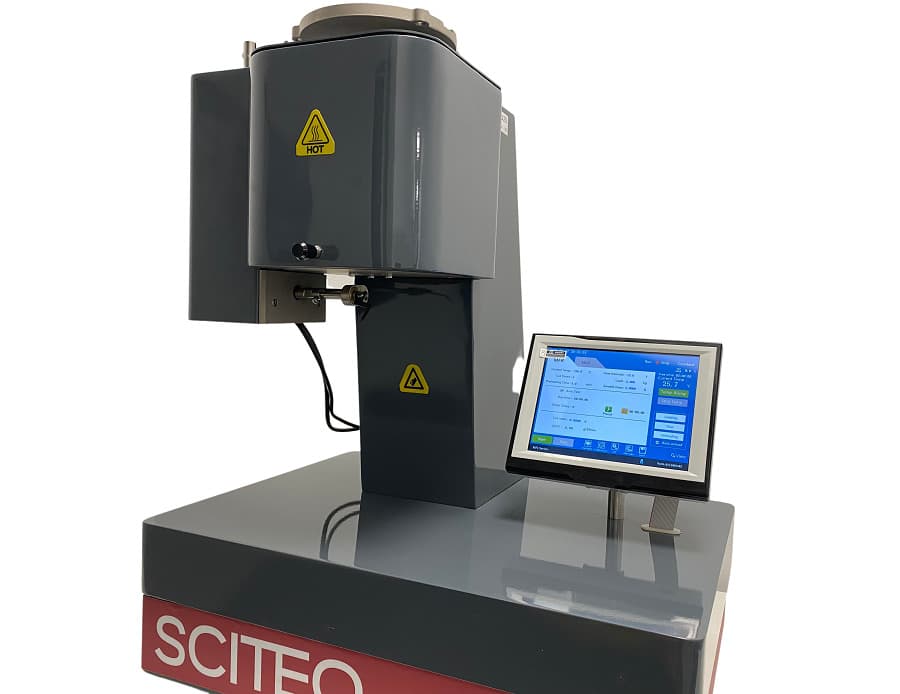

For determining the melt flow index (MFI), melt mass-flow rate (MFR) and melt volume flow rate (MVR) of a wide range of thermoplastic raw materials (granulate) by extruding it in a molten state through a calibrated die using a reference weight.

The user-friendly Melt flow indexer – MFI 450 series is a rigid constructed table apparatus using the latest touch screen controller technology with a very intuitive software. It has audible prompts at the correct time and results calculated and displayed at the end of the test. With the displacement transducer MVR testing can be performed. Supplied with fully equipped weight kit up to 21,6 kg and full accessory kits.

The semi-automatic weight loading device improves use-ability and ensure weights are loaded evenly.

For more information and technical specifications please see the brochure.

Associated equipment

450C incl. auto weight loading.

120°C to 450°C (248°F to 842°F)

±0.2°C

0.01s

approx. 16 minutes (190°C)

Single phase 230V ±10% AC 50-60Hz. 6 Amps

550 x 435 x 880mm (L x W x H)

Weight 62 kg.

There are numerous international standards referring to testing. We supply testing equipment to fulfill any national and international testing standard within our field of business. In case you do not find the standard you are looking for in the below list, please contact us for further information

Standard test method for Melt Flow Rates of thermoplastics by extrusion plastometer.

Testing of Plastics - Determination of the melt flow index of thermoplastics.

Plastics - Determination of the melt mass-flow rate (MFR) and the melt volume-flow rate (MVR) of thermoplastics.

ISO 4427-1:2007 specifies the general aspects of polyethylene (PE) piping systems (mains and service pipes) intended for the conveyance of water for human consumption, including raw water prior to treatment and water for general purposes. It also specifies the test parameters for the test methods to which it refers.

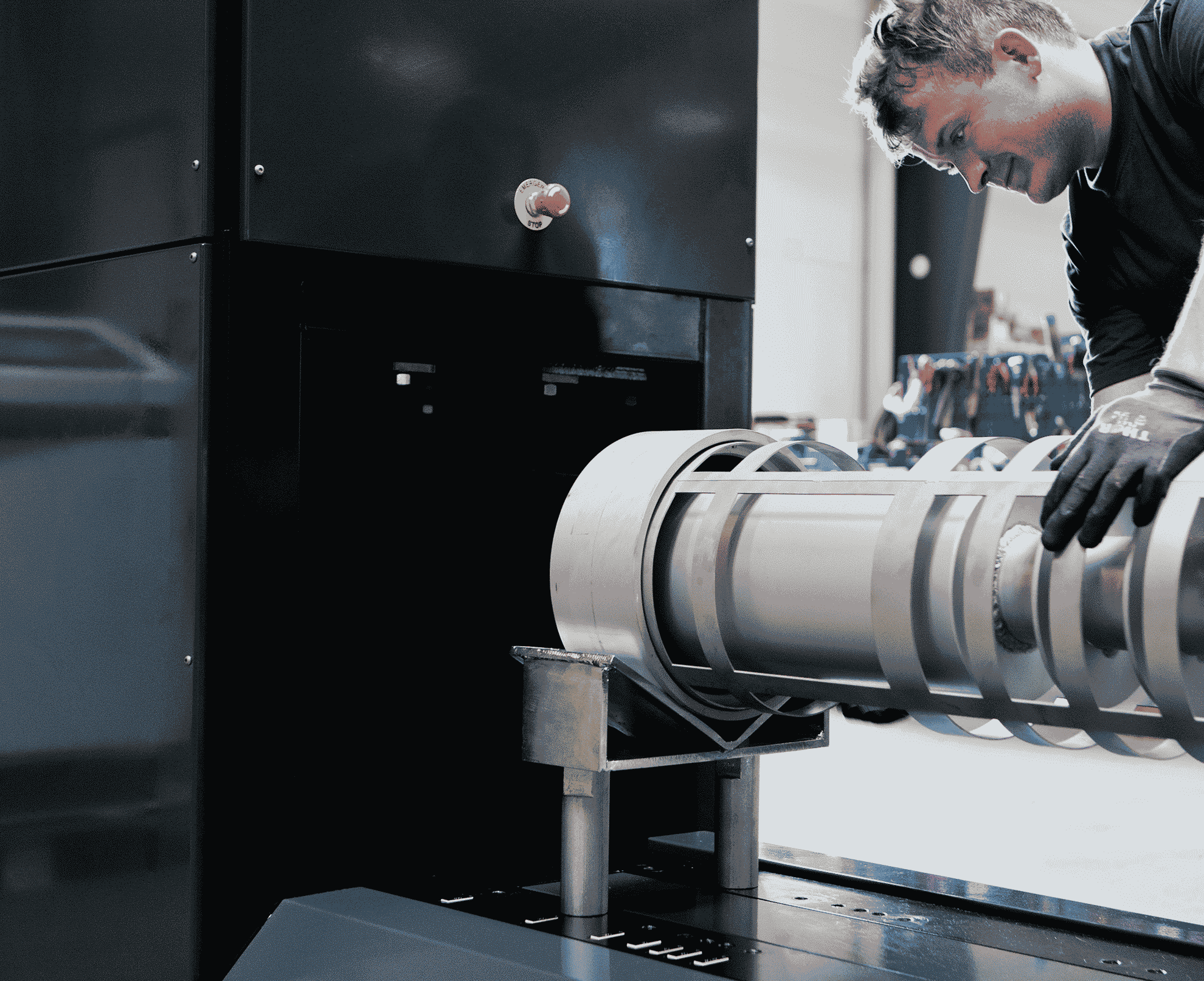

‘The SCITEQ lab saw is running great. It has cut our sample prep time in half’.

View the full caseYour personal contact with us does not end with the commissioning of your test equipment. We also care about the operation of your solution.

We want to ensure optimal up-time based on preventive maintenance and efficient problem solving. You will achieve higher efficiency, high test reliability and a long life-time on your equipment.

We believe service is the key to a fruitful and long lasting cooperatio

Our services

We give you quality tools to produce as cost-effectively as possible, while meeting the highest standards. You will find it is possible to reduce time-to-market saving time on testing.

We help you configure future proof solutions. The SCITEQ equipment and cloud based software is developed by our in-house R&D engineers and manufactured in Europe.

We are close by. We perform global on-site installation as well as service visits and we are of course available for support and advice daily, so you can rest assured your test equipment will have maximum up-time.

The wide range of SCITEQ standard products is available for very short delivery. We will ship directly to your site to help you meet your deadlines. Need a special version? Not a problem, we love the challange.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).