TeraPlast SA, headquartered in Bistrița, Romania, is a leading European manufacturer of plastic piping and system solutions. With diameters ranging from DN 16 to 1000 mm, TeraPlast delivers complete systems for drinking water, sewage, gas, heating, and industrial application

Visit homepageTeraPlast SA, based in Bistrița, Romania, stands as one of the leading manufacturers in the region, offering an extensive range of solutions for infrastructure, construction, and environmental applications. Their portfolio covers drinking water systems, sewer pipes, floor heating systems, gas networks, irrigation solutions, windows, packaging materials, and pellets — with diameters ranging from DN 16 to 1000 mm.

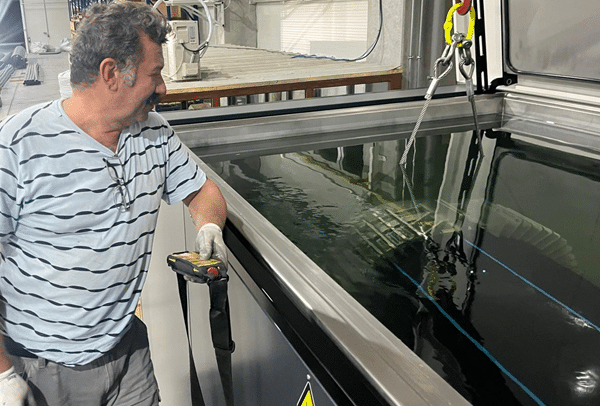

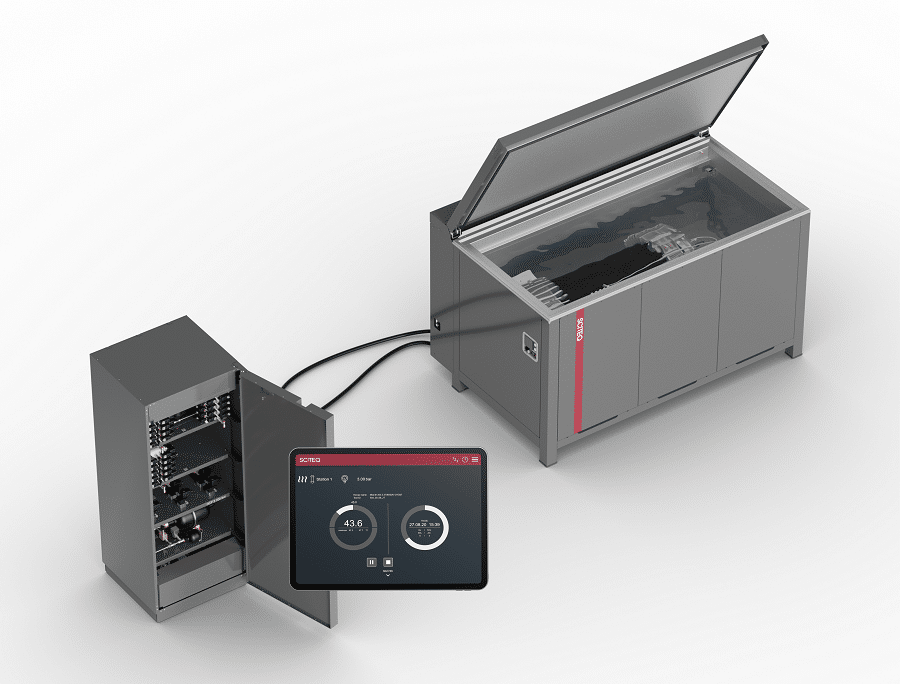

With over a century of experience and a strong commitment to innovation, TeraPlast continues to set high standards in product performance and sustainability. The company operates an accredited laboratory (RENAR), performing comprehensive physical-mechanical, physical-chemical, and performance testing for both in-house and third-party products. This ensures full compliance with international standards and a consistent focus on quality.

Sustainability is at the heart of TeraPlast’s strategy. The company’s mission is to deliver efficient, environmentally responsible solutions through continuous innovation and responsible resource use. TeraPlast’s recycling division and photovoltaic plant demonstrate its firm dedication to reducing environmental impact and promoting circular economy principles.

Our collaboration with the professional and highly skilled team at TeraPlast Romania has been both inspiring and motivating. Working alongside their experts drives us to keep improving our own solutions — to support and prove the sustainability, efficiency, and high performance of TeraPlast’s impressive range of products.

At the core of TeraPlast’s success lies a deep focus on quality-control. Their RENAR-accredited laboratory performs:

Physical-mechanical tests to verify material strength and performance

Physical-chemical analyses for long-term durability

Performance tests for safety and compliance

These rigorous evaluations guarantee consistency, reliability, and full traceability across all production lines — ensuring customers receive proven, high-quality piping systems.

Sustainability is at the heart of TeraPlast’s strategy. The company’s mission is to deliver efficient, environmentally responsible solutions through continuous innovation and responsible resource use. TeraPlast’s recycling division and photovoltaic plant demonstrate dedication to reducing environmental impact and promoting circular economy principles.

Their mission is simple yet powerful: to create efficient, sustainable solutions that benefit both people and the planet.

Working with the professional and skilled team at TeraPlast Romania continues to inspire us. Their drive for technical innovation and environmental responsibility motivates us to keep developing advanced tools and methods that help demonstrate the sustainability, performance, and efficiency of TeraPlast’s impressive product range.

‘

‘

TeraPlast’s portfolio covers a wide variety of materials and applications, including:

#high-density polyethylene pipe (HDPE) systems for reliable water and gas distribution

#HDPE water pressure pipe designed for strength, flexibility, and long service life

#pvc-piping solutions for sewer and wastewater networks

#PP pipes ideal for drainage and industrial installations

#cross-linked polyethylene pipe (PEX) for floor heating and potable water systems

#Polyethylene gas pressure pipes ensuring maximum safety and compliance

Each product is engineered to meet international standards and perform in the most demanding infrastructure environments.

TeraPlast sets annual goals for responsible consumption of natural resources, optimal management of waste generated and increasing the quality of the work climate we offer. They develop products that have a minimal impact on the environment, which are safe for the end-users.

Since 2017 we have had the priviledge to work together with our trusted local agent in Romania, BMF Creativ SRL, Mr. Gheorghiu in supporting TeraPlast installing and servicing test systems. And in 2017 installing solutions for the new TeraPlast Recycling branch.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).