The cyclic test is conducted to replicate the standard lifespan of an object. In many cases the procedure involves filling the obejct with a water and applying pressure, followed by an emptying phase that simulates consumption. This repetitive cycle, performed thousands of times, serves to emulate the object’s long-term usage. Throughout these cycles, critical parameters such as temperature, deformation, and potential leakage are monitored to assess endurance and performance over time.

The unique and advanced open-loop system of the SCITEQ Cyclic Pressure Testing System providies pressure cycles in the range from 2-100 bar with accuracy ≤ ± 1 bar of set pressure.

The unique water cooled linear servo drive combined with high-resolution linear encoders offer considerably higher accuracy compared with conventional systems.

The system offers accuracy of ± 1 bar on setup pressure and saw-tooth pressure cycles up to 3600 cycles/hour (adjustable) with a sample volume 90 mL / cycle (piston pump). The control touch panel with intuitive software solution offering a.o. automatic settings according to the specific sample ‘fingerprint’ as well as the following features:

Easy integration of complex algorithms

Rapid controller startup

Automatic bleed function

Software access via browser

Remote access for service

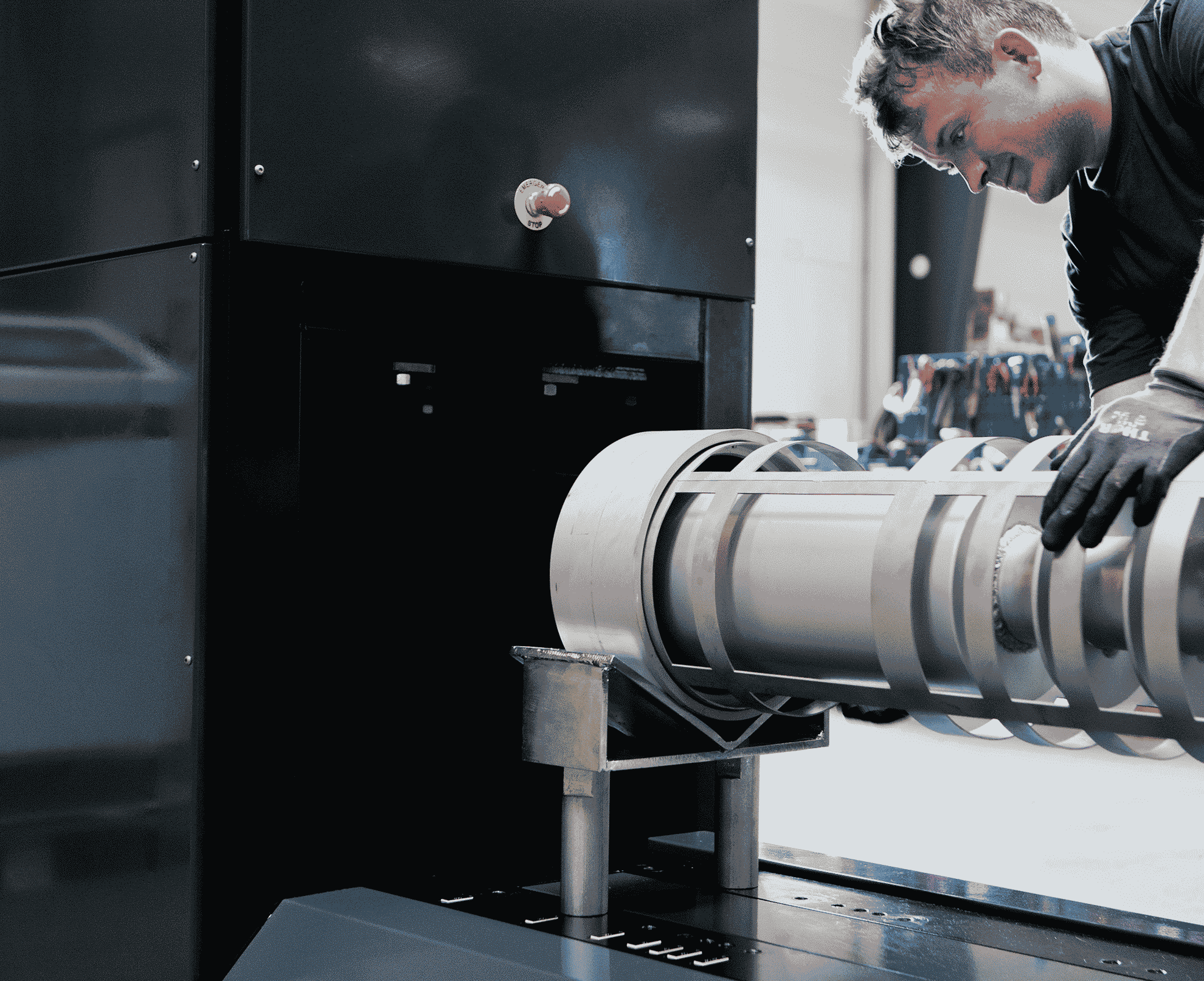

The test specimen is filled with water and subject to pressure cycles generated from individual piston pressure cylinders driven by servo-drive to adjust the pressure range and curve.

The automatic bleed function will always ensure that the sample is sufficiently aired-out (bleeding) before each test. This essential feature ensures accuracy is maintained during the complete test. Test cycles are 100% stabile and rigid due to the ‘valve less’ design in combination with the auto bleed function. Furthermore the need for maintenance is minimal due to both the ‘valveless’ system and the magnetic drive.

For more information and technical specifications please contact us

2-100 bar*

*The pressure/volume ratio is to be configured before order, as it is not possible to achieve max. volume at max. pressure.

Max. 90 ml.

0,16-1 Hz. 10-60 strokes/min. Min. to max. pressure/min.

+/- 1 stroke/min.

0,1 bar

+/- 1 bar

sinus or triangular shape to be selected.

0,5% FS (25 °C ambient)

18 KW, 26 A

3x400V + Neutral, 50/60 Hz

There are numerous international standards referring to testing. We supply testing equipment to fulfill any national and international testing standard within our field of business. In case you do not find the standard you are looking for in the below list, please contact us for further information

Specifies requirements for flexible, leak-resistant joints in PVC and PE pipes for gravity-flow sewer systems. It defines hydrostatic pressure tests and assembly procedures.

Specifies methods for leak tightness and pressure cycling tests on plastics fittings. Explicitly mentions cyclic internal pressure tests as part of performance testing.

TeraPlast sets annual goals for responsible consumption of natural resources, optimal management of waste generated and increasing the quality of the work climate we offer. They develop products that have a minimal impact on the environment, which are safe for the end-users.

View the full caseYour personal contact with us does not end with the commissioning of your test equipment. We also care about the operation of your solution.

We want to ensure optimal up-time based on preventive maintenance and efficient problem solving. You will achieve higher efficiency, high test reliability and a long life-time on your equipment.

We believe service is the key to a fruitful and long lasting cooperatio

Our services

We give you quality tools to produce as cost-effectively as possible, while meeting the highest standards. You will find it is possible to reduce time-to-market saving time on testing.

We help you configure future proof solutions. The SCITEQ equipment and cloud based software is developed by our in-house R&D engineers and manufactured in Europe.

We are close by. We perform global on-site installation as well as service visits and we are of course available for support and advice daily, so you can rest assured your test equipment will have maximum up-time.

The wide range of SCITEQ standard products is available for very short delivery. We will ship directly to your site to help you meet your deadlines. Need a special version? Not a problem, we love the challange.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).