For ASTM D1598, D1599 & ISO 1167 testing.

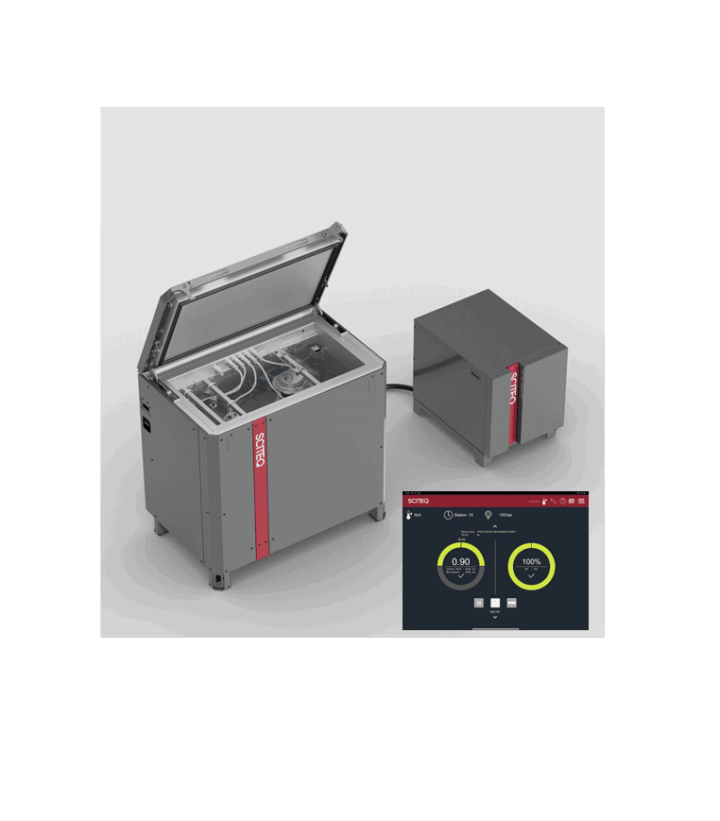

liteSERIES is the smart, fast, and reliable solution for internal hydrostatic pressure testing. Designed for efficiency, it offers quick setup and easy maintenance, while also ensuring extremely precise regulation and flow—making it a cost-effective choice for smaller test labs.

The lite equipment is controlled via the intuitive browser-based interface. It’s extremely user-friendly and enables easy operation of the tests with features such as dynamically adjusted finish time, full station overview and click less maneuvering.

Need a quote?

The dedicated burst test station in burstONE performs internal hydrostatic pressure testing within the range o-200 bar at a max. flow of up to 15 l/min. The airless burst test is performed with water.

Learn moreThe liteFIVE test unit offers 5 independently operating airless pressure stations in a compact cabinet. For internal hydrostatic pressure testing within the range 0-100 bar at a max. flow of up to 2 l/min

Learn moreliteTANK is designed for maximum efficiency and user-friendly operation. Ideal for smaller laboratories. Equipped with high-quality insulation and a circulation pump, it ensures uniform temperature while reducing energy consumption.

Learn moreliteCAPS are produced for sealing off pipe samples for internal pressure testing. Optimized lightweight design for fast and easy handling. A more sustainable and cost-effective solution. With/without tie-bar. Size range Ø12mm up to Ø280mm

Learn moreBurst Pressure testing is performed with water. This test is often performed as a pre-production test to meet safety and quality standards. The test specimen is filled with water and pressurized untill bursting. The pressure ramp is controlled by the SIGMA software ensuring accuracy and test data analysis. The pressure range for the SCITEQ standard test system is up to 200 bar. The unique software & intelligent dynamic regulation ensures the most stable and linear pressure regulation in the market. Learn more about the test process

Validating Product Performance

Hydrostatic pressure testing, conducted in accordance with ISO 1167, serves as a reliable method for assessing a pipe or fitting’s resistance to internal pressure in a controlled laboratory setting. This standardized approach ensures consistent and repeatable results, forming the basis for product certification, quality assurance during production, and the development of product enhancements. By enabling direct comparison across different batches, materials, and suppliers, ISO 1167 and ASTM D 1598 testing supports ongoing compliance and performance verification throughout the product lifecycle

SCITEQ Pressure Test systems can perform tests in compliance with numerous test standards. In addition to plastic pipe materials, our solutions accommodates testing for applications in hydrogen storage, steel piping, tubing, glass fibre cables etc.

Contact our test specialist to learn about the possibilities for your testing.

Contact us

Learn more about our hydrogen testing equipment for hydrogen storage vessels and tanks.

Our experts are ready to dsicover your possibilities and answer your potential questions

The quality validation testing process for hydrogen vessels and tanks plays a important role in minimizing the inherent risks associated with hydrogen storage, given the highly flammable and potentially dangerous nature of the gas.

The high-pressure test of hydrogen vessels, particularly for internal hydrostatic pressure, involves subjecting hydrogen storage tanks or vessels to extreme pressures to ensure their structural integrity, safety, and compliance with regulatory standards. For hydrogen vessels, especially composite tanks or reinforced vessels, these tests are crucial to validate that they can safely store hydrogen under high-pressure conditions, which is common in fuel cell vehicles, hydrogen storage systems, and other industrial applications.

Hydrostatic testing is generally preferred for its safety advantage, as water is less hazardous than gas under high pressure.

Pressure testing of composite pressure tanks and vessels is a key safety test where the tank is filled with water or another non-compressible fluid, then pressurized beyond its working pressure. The goal is to ensure the tank can withstand pressure without rupturing. Procedure: The tank is filled with water, which is less hazardous than gas. It is pressurized to approximately 1.5 times its maximum operating pressure. The tank is checked for leaks or deformations. SCITEQ equipment is specifically engineered to evaluate the strength, leakage, and deformation of various objects using hydrogen or other fluids as the testing medium.

The SCITEQ Burst Test unit is designed for testing the bursting strength of hydrogen composite pressure vessels by applying water pressure under ambient conditions. The vessel is pressurized until it either reaches the burst point or the target pressure (up to a maximum of 2,500 bar). Compliance with both national and international standards, as well as customer requirements, necessitates batch testing to verify the performance and safety of hydrogen composite pressure vessels.

The cyclic test aims to simulate the expected lifespan of an object. For a hydrogen storage tank, this process entails filling the tank with a fluid and applying pressure, followed by an emptying phase that mimics gas usage. This repetitive cycle, executed thousands of times, replicates the long-term operation of the vessel. During these cycles, essential parameters such as temperature, tank deformation, and potential leaks are continuously monitored to evaluate the tank's performance over time. The SCITEQ Cyclic Pressure Testing System features a unique and sophisticated open-loop system that provides pressure cycles ranging from 2 to 100 bar, with an accuracy of ± 1 bar of the set pressure.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).