PSILab is the preeminent independent third-party plastic pipe testing ISO 17025 accredited laboratory in North America. Resin and pipe manufacturers as well as engineers and installers depend on PSILab to help them understand the quality and performance of their products.

‘From cell classification testing to pipe stiffness to hydrostatic pressure testing to elevated temperature testing, SCITEQ’s equipment helps us get the work done efficiently, accurately, and safely. We are very pleased with our ongoing partnership with SCITEQ and we appreciate the fact that their state-of-the-art instruments play a vital role in our laboratory testing operations’. Steve Ferry, PSILab President and Laboratory Director.

SCITEQ is proud to be PSILab’s supplier of pipe test solutions since 2015 providing equipment and service for pressure test, universal testing and melt flow index.

Visit homepage

SCITEQ’s test equipment must provide reliable results in order to live up to PSILab’s mission; to deliver solutions when pipe producers need certainty. The SCITEQ Dynamic Pressure Control (DPC) system© and unique ABX valve ensures consistent and unparalleled pressure accuracy, no matter the sample size.

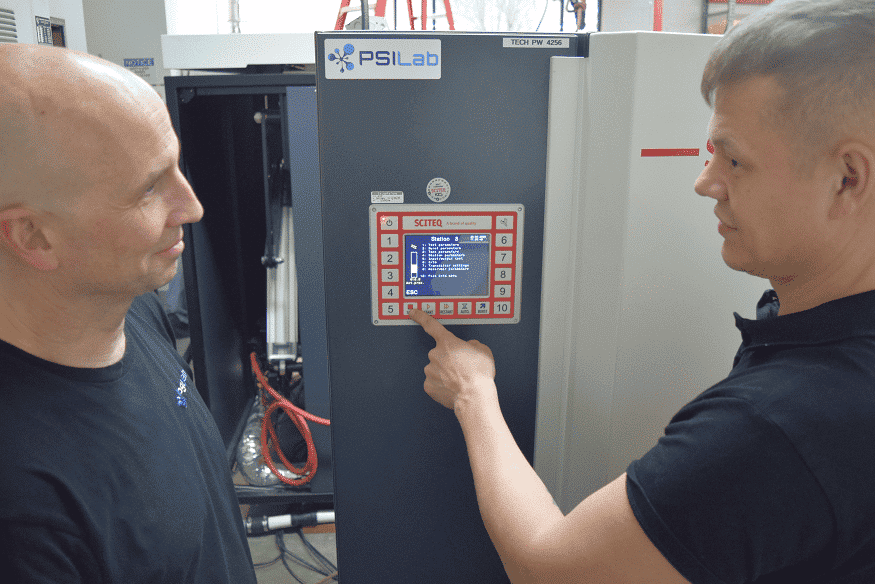

SCITEQ Service engineer Kim Køpke, who is in charge of service and support at PSILab states “It’s our job to make sure that PSILab’s test results are accurate and reliable and to help ensure maximum up-time on the test equipment”.

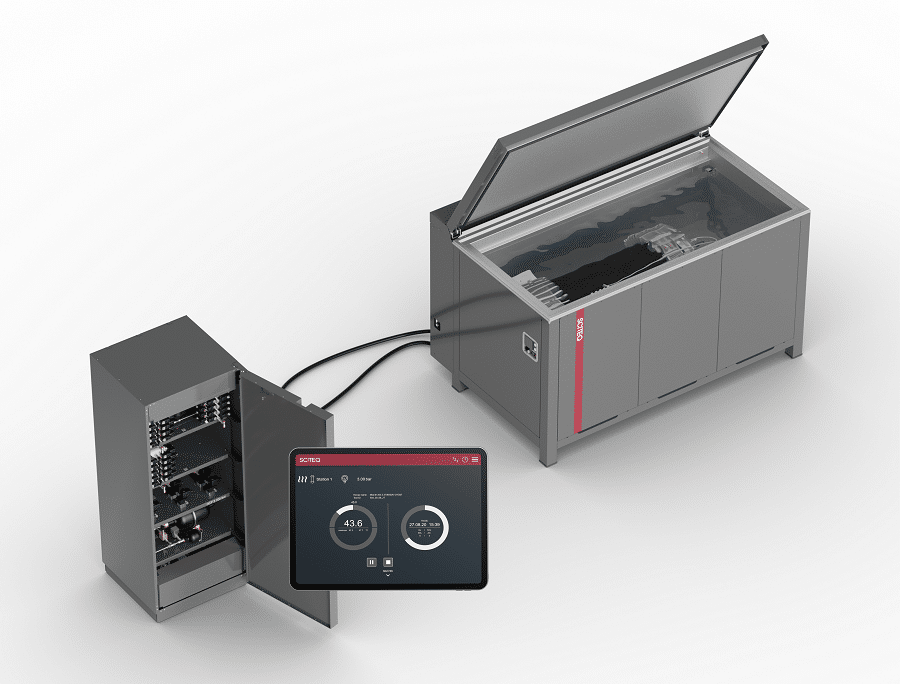

PSILab offers tests of any pipe material and diameter, which calls for scalable hardware and intuitive software. PSILab’s complete pressure test solution consists today of 80 individual X-ACT pressure stations with a capacity of up to 160 bar for hydrostatic testing as well as a designated stations for burst test at 200 bar.

Uniform conditions and reliable results

The 80 pressure stations are connected to SCITEQ thermo tanks of various sizes offering capacity for numerous pipe sample configurations of up to OD 630mm. The tanks’ compact thermal insulation, innovative heating elements and circulation pumps ensure a constant and uniform temperature between 20-95°Celsius.

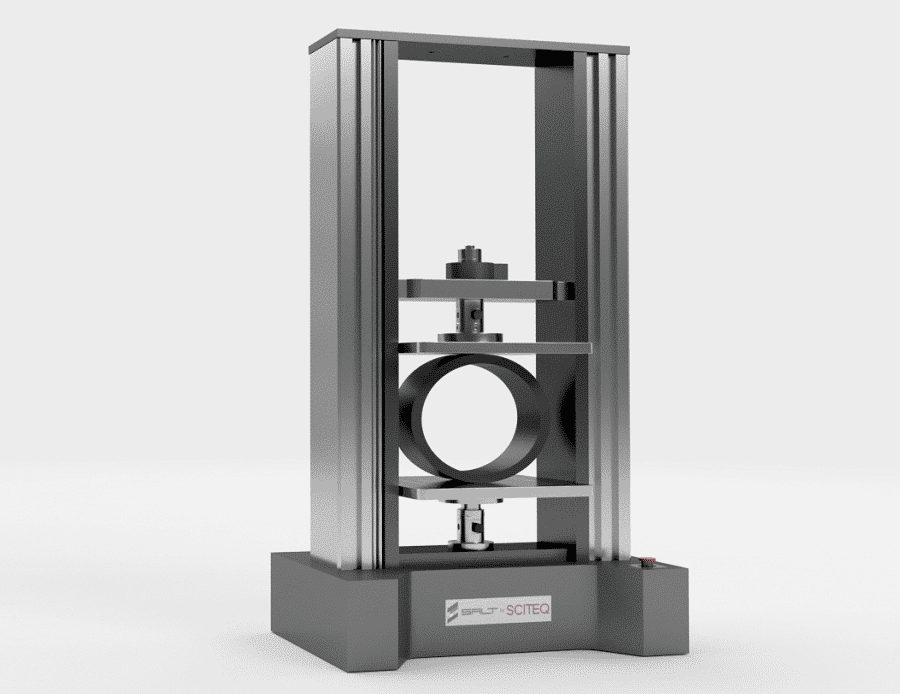

Durable and versatile UTM

The SCITEQ UTM is equally suitable for routine quality control testing as for complex multi-stage tests as they are highly customizable. PSILab’s SCITEQ UTM is a 4-column solution with deflection gauge and extensometer system. Suitable for large diameter pipe testing of up to 100kN. The software enables a large range of different test procedures according to international standards.

‘From cell classification testing to pipe stiffness to hydrostatic pressure testing to elevated temperature testing, SCITEQ’s equipment helps us get the work done efficiently, accurately, and safely’

Steve Ferry

0-95 ° C tank, temperature setting +/- 0,1 ° . THe SIGMA thermo test tank design reduces energy consumption and ensure uniform temperature during conditioning and testing.

View products

The SCITEQ SCT Universal Testing Machines offers a wide range of test used in the plastics industry. The UTMs perform tensile, compression, and bending tests according to a large variety of international standards i.e. ISO 527, ISO 6259, ISO 9967, ISO 9969, ISO 13953, ASTM D 638, DIN 53 504

View productsPSILab is serviced by SCITEQ Sales Director Peter Sejer and SCITEQ agent in North America, Mr. Stefan Killinger. Service engineer Kim Køpke is PSILab’s go-to-person on technical advice and service.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).