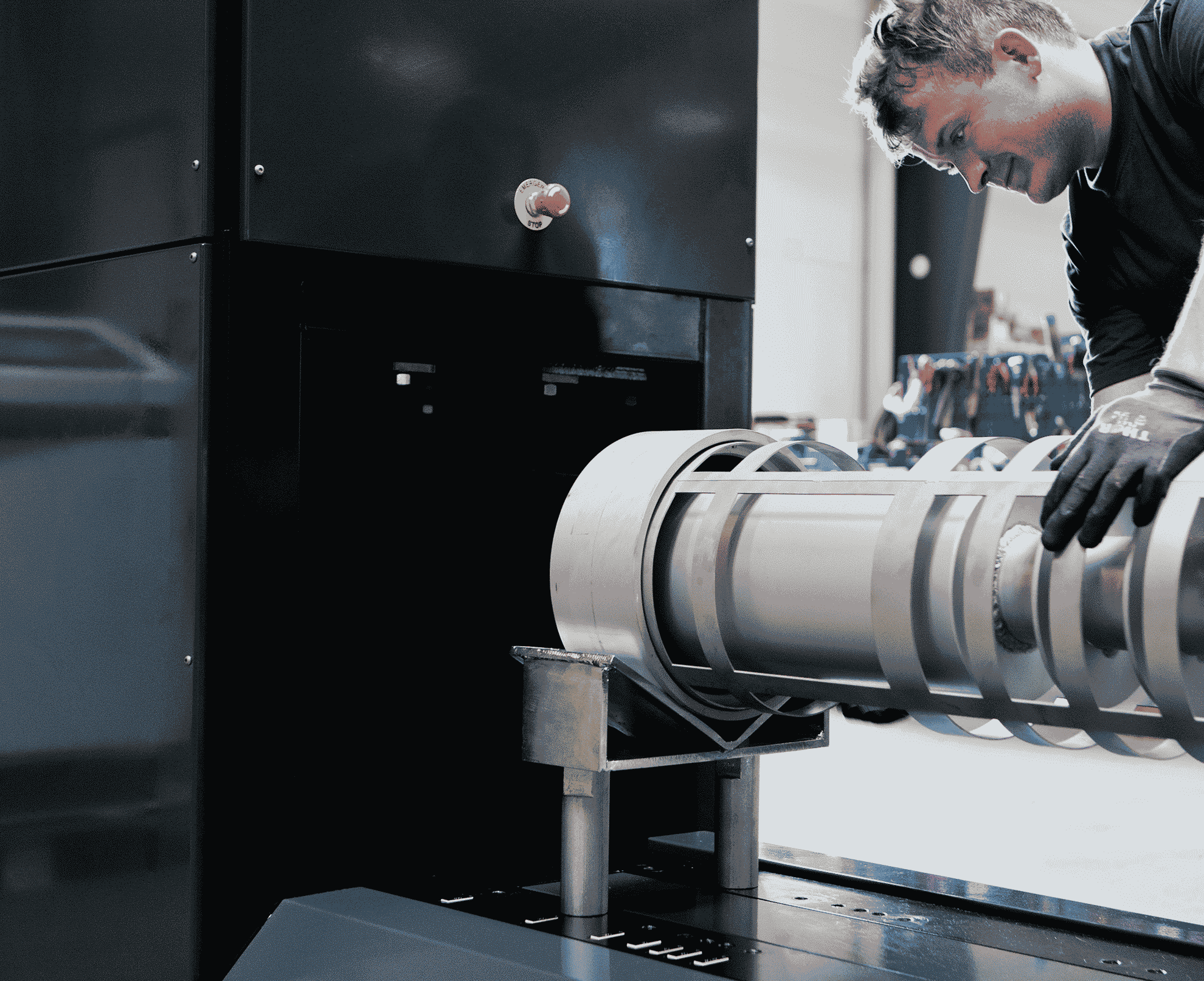

Die SCITEQ Kerbfräser fräst die Kerbe automatisch nach vordefiniertem Rezept mit einem Winkel von 60 Grad und mit einer Geschwindigkeit von bis zu 150 mm pro Minute mit einer Geschwindigkeit von bis zu 150 mm pro Minute in einer kontrollierten Tiefe in die Rohrwand. Die benutzerfreundliche Oberfläche sorgt bei jedem automatischen Fräsvorgang für zuverlässige Ergebnisse und trägt dazu bei, die Vorbereitungszeit erheblich zu verkürzen und damit die Prüfverfahren zu optimieren.

Die Maschine ist so konstruiert, dass sie eine Kerbe im 60-Grad-Winkel ausführen kann. Fräswerkzeugabmessungen Ø76,2 x 12,5 x 25,4 mm doppeltem rechtwinkliger Frässchnitt bei 700 U/min.

Einfache Einstellung

Der SCITEQ Kerbfräser ist leicht einstellbar für Rohrdimensionen von DN 40 bis DN630mm. Geben Sie einfach die SDR-Klasse und die Länge des Rohres ein und passen Sie die parallele Adapterplatte an. Die Rohrrotator zentriert und dreht das Rohr automatisch um 90° für eine optimale Präzision der Ausklinkungen. Die Lösung gewährleistet auch bei ovalen Rohren die richtige Schnitttiefe.

Sicher und zuverlässig

Der Schnitt wird sicher von der Fernbedienung aus eingeleitet, indem der Fräser von der Unterseite der Rohrprobe nach oben gefahren wird. Ein direkter Zugriff auf den Fräser während des Betriebs wird verhindert. Die eingebaute Absaugung entfernt die Späne und sorgt für eine gefährdungsfreie Umgebung und einen geringen Wartungsaufwand der Maschine selbst.

Weitere Informationen und technische Daten entnehmen Sie bitte der Broschüre.

Zugehörige Ausrüstung

Außendurchmesser 40-630 mm

Min: 5 / Max:100 mm.

Min. 400- max. 1900 mm

650 mm bei voller Tiefe

700 (über Touchscreen einstellbar)

Innerhalb von 0,2 mm.

Innerhalb von 1 mm.

3019 x 1450 x 2481 mm (LxBxH)

Ungefähr: 900 Kilogramm.

Es gibt zahlreiche internationale Normen, die sich auf das Prüfen beziehen. Wir liefern Prüfgeräte zur Erfüllung aller nationalen und internationalen Prüfnormen in unserem Geschäftsfeld. Sollten Sie die von Ihnen gesuchte Norm in der untenstehenden Liste nicht finden,kontaktieren Sie unsbitte unter für weitere Informationen

Rohre, Formstücke und Bauteile aus thermoplastischen Kunststoffen für den Transport von Fluiden - Bestimmung der Innendruckfestigkeit Teil 1: Allgemeines Verfahren, Teil 2: Vorbereitung von Rohrprüfkörpern, Teil 3: Vorbereitung von Bauteilen, Teil 4: Vorbereitung von Baugruppen.

Polyolefin-Rohre für den Transport von Flüssigkeiten - Bestimmung des Widerstandes gegen Rissausbreitung - Prüfverfahren für langsames Risswachstum an gekerbten Rohren (Kerbprüfung).

Die SCITEQ-Laborsäge läuft großartig. Sie hat unsere Probenvorbereitungszeit um die Hälfte reduziert.

Den ganzen Fall ansehenIhr persönlicher Kontakt mit uns endet nicht mit der Inbetriebnahme Ihrer Prüfgeräte. Wir kümmern uns auch um den Betrieb Ihrer Lösung.

Durch vorbeugende Wartung und effiziente Problemlösung wollen wir eine optimale Betriebszeit sicherstellen. So erreichen Sie eine höhere Effizienz, eine hohe Prüfsicherheit und eine lange Lebensdauer Ihrer Geräte.

Wir glauben, dass Service der Schlüssel zu einer fruchtbaren und langjährigen Zusammenarbeit ist.

Unsere Dienstleistungen

Wir geben Ihnen Qualitätswerkzeuge an die Hand, mit denen Sie so kosteneffizient wie möglich produzieren und gleichzeitig die höchsten Standards erfüllen können. Sie werden feststellen, dass es möglich ist, die Zeit bis zur Markteinführung zu verkürzen und Zeit für Tests zu sparen.

Wir helfen Ihnen, zukunftssichere Lösungen zu konfigurieren. Die SCITEQ-Geräte und die cloudbasierte Software werden von unseren eigenen Forschungs- und Entwicklungsingenieuren entwickelt und in Europa hergestellt.

Wir sind in Ihrer Nähe. Wir führen weltweit Vor-Ort-Installationen sowie Servicebesuche durch und stehen Ihnen natürlich täglich mit Rat und Tat zur Seite, so dass Sie sicher sein können, dass Ihre Prüfgeräte eine maximale Betriebszeit haben.

Die breite Palette der SCITEQ-Standardprodukte ist für sehr kurze Lieferzeiten verfügbar. Wir liefern direkt an Ihren Standort, damit Sie Ihre Fristen einhalten können. Sie benötigen eine Sonderanfertigung? Kein Problem, wir lieben die Herausforderung.

Für Fragen, Kommentare und Anregungen stehen wir Ihnen gerne zur Verfügung. Wir freuen uns darauf, von Ihnen zu hören.

Sie können uns gerne über das unten stehende Kontaktformular kontaktieren.

Wir bemühen uns, alle Anfragen innerhalb von 24 Stunden (an Werktagen) zu beantworten.