A pipe/fitting sample is placed on a gravel bed and covered with gravel. A constant vertical load is applied via the gravel and temperature cycling is performed. Vertical deflection of the test piece is measured. A further feature is the optional conveyor system that eases gravel handling in terms of filling and emptying the box. The system uses tanks containing hot and cold water supplies depending on test method.

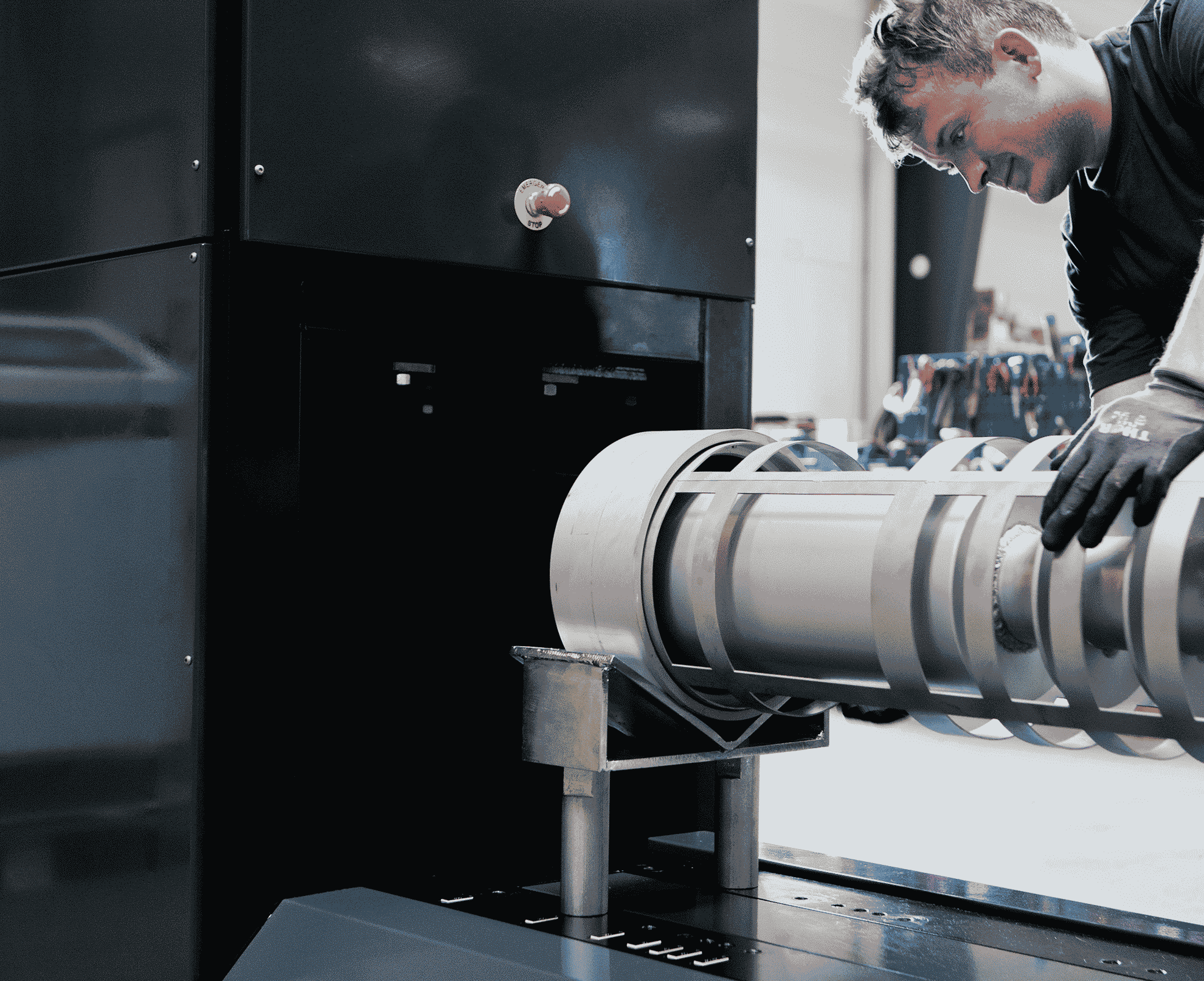

The box loading system comprises three main parts; the box loader itself with compression plate, adjustable sides and pipe/fitting inlet/outlet, the tank system and the control cabinet combined with a chiller (chiller only needed for method A). Additional optional parts are the gravel conveyor system and the gravel storage container.

SCITEQ’s system may be configured to perform method A, B or both. The BLT is suitable for pipe sizes Ø110-510mm.

The box loader itself is heavy-duty and constructed in a way to allow a high degree of flexibility in terms of size adjustability depending on the actual pipe dimension and composition (straight pipe or assembly) to be tested. The gravel will cause severe wear of the inner box and thus the inner box has been constructed in wood which is easily replaceable.

The box is accessible in more ways for instance to allow tamping of the gravel, to position the test piece, to load and unload gravel etc.

The tank system in stainless steel consists of two water tanks (depending of test method). Return water is lead back to the correct water tank thus saving energy. Continuously circulation in the tanks ensures consistent temperature.

The control cabinet contains high quality components carefully chosen for their compatibility worldwide. The state-of-the art touch panel is very service friendly and offers excellent functionality.

Touch panel

The box loader is operated from a user-friendly control touch panel PC offering:

For more information and technical specifications please request our brochure.

Associated equipment

method A: Ø110 up to Ø190 mm.

method B: Ø190 up to Ø510 mm.

50-60 kN +/- 2.

method A: 85 degrees C (+/-2)

method B: 50 degrees C (+/-2)

method A: 5-22 degrees C

0,35 bar .

+/- less than 1 degree C.

min. 2500 cycles

3 x 400V, 50Hz (TN-S).

box loader: 1700x1800x2200 mm (LxWxH)

tank systems with two tanks and control cabinet: 2800x1800x2200mm (LxWxH)

chiller: 800x700x1300mm (LxWxH)

gravel storage container: 1700x1800x2200mm (LxWxH)

gravel conveyor system: Height 4550mm (LxWxH) (Optional)

Weight: approx. 3 ton

There are numerous international standards referring to testing. We supply testing equipment to fulfill any national and international testing standard within our field of business. In case you do not find the standard you are looking for in the below list, please contact us for further information

Thermoplastics piping systems for non-pressure underground drainage and sewerage - Test method for resistance to combined temperature cycling and external loading.

‘The SCITEQ lab saw is running great. It has cut our sample prep time in half’.

View the full caseYour personal contact with us does not end with the commissioning of your test equipment. We also care about the operation of your solution.

We want to ensure optimal up-time based on preventive maintenance and efficient problem solving. You will achieve higher efficiency, high test reliability and a long life-time on your equipment.

We believe service is the key to a fruitful and long lasting cooperatio

Our services

We give you quality tools to produce as cost-effectively as possible, while meeting the highest standards. You will find it is possible to reduce time-to-market saving time on testing.

We help you configure future proof solutions. The SCITEQ equipment and cloud based software is developed by our in-house R&D engineers and manufactured in Europe.

We are close by. We perform global on-site installation as well as service visits and we are of course available for support and advice daily, so you can rest assured your test equipment will have maximum up-time.

The wide range of SCITEQ standard products is available for very short delivery. We will ship directly to your site to help you meet your deadlines. Need a special version? Not a problem, we love the challange.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).