The new SIGMA TCA system has 6 individual sample string with individual flow control and temperature measuring. The system is controlled by the software with extremely user friendly interface run from any browser enabled device (iPad, laptop, smart phone)

All test parameter can be modified if wanted, especially useful for R&D where testing is not according to a specific standard. Furthermore data such as batch no, machine no. Customer name, operator name etc. can be entered, which is valuable to the test report.

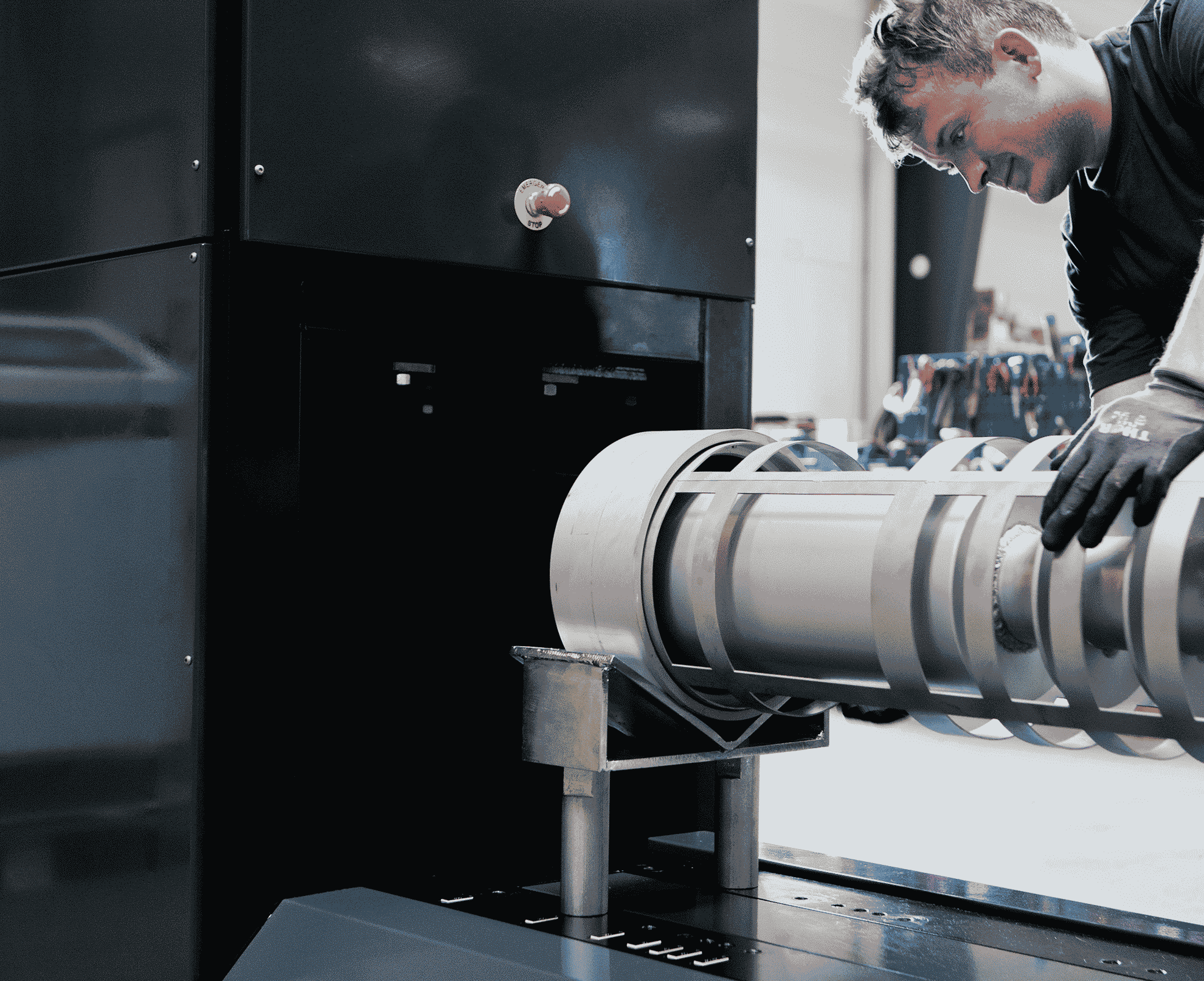

Safe and easy

The transperant test chamber allows for easy access while also enabling full visual inspection during test.

The system has non-pressurized water reservoirs ensuring safe operation as well as minimizing maintenance costs. The test system is designed to minimize the volume of pressurized water.

Emergency shut-down systems are installed to ensure a 100% safe operation environment. All doors are locked electronically once the pressure pump is running as a safety feature.

Browser based software – full view

The complete TCA system is operated from a user-friendly browser based software optimized for touch.

The “One page” overview provides full view of all stations. Multiple filtering options. Displaying ongoing tests listed in order ranked according to ‘attention urgency’/ time left to completion. For each station an individual dash board will provide more detailed info on the current status of the test and a graph of current test in real time provides full details about pressure and temperature, enabling zooming in and monitoring current test, directly from the handheld UX device.

Recipe system

The Temperature cycling test – TCA software offers a recipe system enabling quick start and repeat of tests. When parameters are pre-programmed; set pressure, cycle time, specimen type it only takes the operator a couple of clicks to fast and easy start and repeat test. The recipe guide will guide the operator through the parameter setup needed for easy loading and start of test.

Test paramaters

All (most) every test parameter can be modified if wanted, especially useful for R&D where testing is not according to a specific standard. Furthermore data such as batch no, machine no. Customer name, operator name etc. can be entered, which is valuable to the test report.

Accuracy and energy saving

The pressure is delivered by high quality Grundfoss pumps and the system has an automatic water filling and circulation feature ensuring full tank and consistent temperatures. The automatic energy saving system controlled by the SCITEQ SIGMA software delays hot water flow to the cold water tank and visa versa during hot and cold water cycle changeover.

High quality components and an extremely precise electromagnetic flow measurement ensures high accuracy with deviation of only +/- 0,4%.

Testing results are easily transferred to i.e. Excel for further processing.

For more information and technical specifications please see the brochure.

Associated equipment

6 individual samples

1" male thread BSP

Yes

95° degrees Celsius

15° degrees Celsius

Within */- 2 K

17

10 bar (16 bar on request)

60 seconds

Yes

Yes

Available on request. Monitoring total flow or per sample.

Included in software interface

Browser based SIGMA software interface - accessible from any device – any time, anywhere.

Included

400V V+PE+N 50/60Hz.

Normal tap water 1,5 - 4 bar

Inner tank: Certified stainless steel AISI 304

Frame & cover plates: Coated aluminium

Supply frame: 4200x2300x2360 mm (LxWxH) Weight approx.: 2400 kgs.

Test cabinet: 4460x1450x2040 mm (LxWxH) Weight approx.: 700 kgs.

Varios layout configurations

There are numerous international standards referring to testing. We supply testing equipment to fulfill any national and international testing standard within our field of business. In case you do not find the standard you are looking for in the below list, please contact us for further information

Thermoplastics pipes and associated fittings for hot and cold water for domestic purposes and heating installations in buildings - Specification for chlorinated polyvinyl chloride (PVC-C) pipes and associated fittings and solvent cement.

Compound pipes in the drinking water installation - Requirements and testing.

Compound pipes in the drinking water installation - Requirements and testing.

Compound pipes in the drinking water installation - Requirements and testing.

Plastics piping systems - Thermoplastics pipes and fittings for hot and cold water - Test method for the resistance of mounted assemblies to temperature cycling.

Plastics piping systems for hot and cold water installations - Guidance for classification and design.

Plastics piping systems – Thermoplastics pipes and fittings for hot and cold water – Test method for the resistance of mounted assemblies to temperature cycling (equivalent to ISO 19893).

Plastics piping systems - Thermoplastics pipes and fittings for hot and cold water - Test method for the resistance of mounted assemblies to temperature cycling (equivalent to EN 12 293).

‘The SCITEQ lab saw is running great. It has cut our sample prep time in half’.

View the full caseYour personal contact with us does not end with the commissioning of your test equipment. We also care about the operation of your solution.

We want to ensure optimal up-time based on preventive maintenance and efficient problem solving. You will achieve higher efficiency, high test reliability and a long life-time on your equipment.

We believe service is the key to a fruitful and long lasting cooperatio

Our services

We give you quality tools to produce as cost-effectively as possible, while meeting the highest standards. You will find it is possible to reduce time-to-market saving time on testing.

We help you configure future proof solutions. The SCITEQ equipment and cloud based software is developed by our in-house R&D engineers and manufactured in Europe.

We are close by. We perform global on-site installation as well as service visits and we are of course available for support and advice daily, so you can rest assured your test equipment will have maximum up-time.

The wide range of SCITEQ standard products is available for very short delivery. We will ship directly to your site to help you meet your deadlines. Need a special version? Not a problem, we love the challange.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).