The unique SIGMA software & valve solution enables stable and linear high pressure regulation. 50+ years of research & experience supplying high-end test equipment worldwide is brought to use in this unique & proven technology – guaranteeing you can perform high pressure testing up to 1500 bar/21.750 psi.

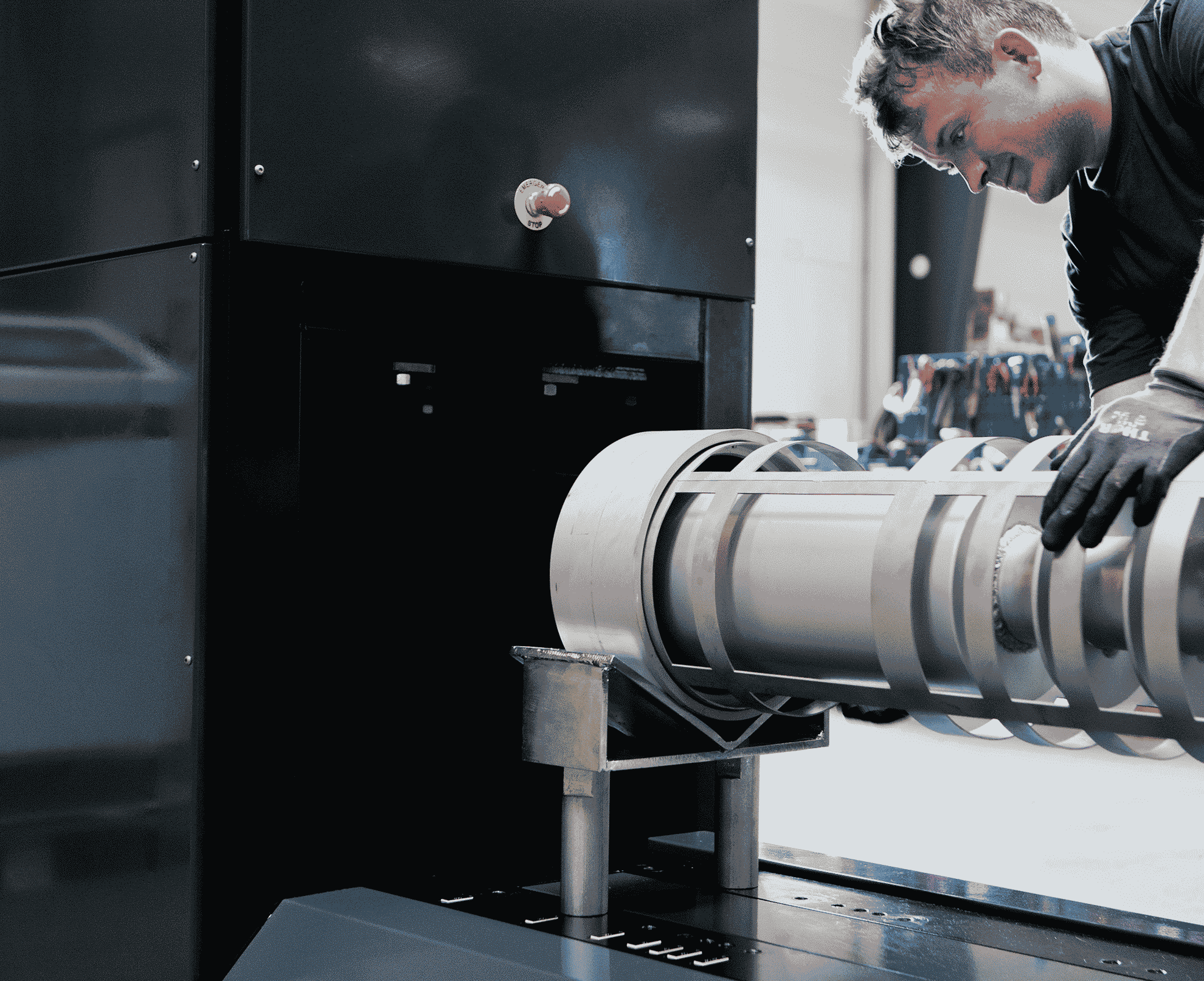

The system consists of modular airless pressure modules designed to fit into a compact standard cabinet. The cabinet can be installed with 5, 10 or 15 independently operating pressure stations up to 1500 bar/ 21.750 psi and 8,5 l/m per station. The modularity enables easy extension with 5 station per module – up to a total of 15 high pressure stations.

One cabinet can contain up to 15 High Pressure stations delivering a flow of max. 8,5 liters per minute can be installed in one cabinet. SIGMA is a closed-loop airless system allowing you to seamlessly run both static, step and burst tests according to the relevant/given international standards.

SIGMA high pressure test solution determines the resistance (both long term and short term) to internal pressure on thermoplastic pipes, fittings and assemblies for conveyance of fluids. The system offers a test solution complying with the standards ISO 1167, EN 12 293 ASTM, D1598 and ASTM D 1599 and equivalent. The system can be configured to perform both Static, Burst and Step test.

SCITEQ has developed a unique proportional valve solution ensuring high pressures are maintained with unparalleled accuracy even when testing at high pressures up to 1500 bar /21.750 psi. Static, burst and cyclic testing can all be accommodated. This built-in precision valve ensures precise pressure control and the most stable and linear pressure regulation in the market.

The built-in alarm light visually alerts the operator instantly in case of irregularities in the ongoing test.

The browser-based SIGMA software is accessible from any device – any time, anywhere. The advantages are among others:

The fast and extremely easy to use interface enables easy operation and control of few as well as many simultaneous pressures tests with features such as dynamically adjusted finish time, full station overview and click less maneuvering.

Recipes are quickly set-up, saving time when starting up a new test (diameter) as well as repeating saved test parameters. Up to four different user-levels from Basic to Advanced, ensuring not only easy operation, but also offering simultaneous ‘view-only’ access for your interested partners and clients.

For more information and technical specifications about the SIGMA high pressure pipe testing solution please go to SIGMA software.

Reports can be configured to include all data or selected data. Tick boxes from the top menu to choose the data you wish to include.

The Test Data can be shown in different languages and units of measure.

0-500 bar regulated pressure output

500-1000 bar regulated pressure output

1000-1500 bar regulated pressure output

Max. flow 8,5 l/min

5, 10 or 15 high pressure stations

3 phase 200-240V, 50/60 Hz OR 3 phase 380-400V, 50/60 Hz

mains water supply, 2-6 bar

lead to gravity fed waste water

1504 x1214x1923mm (WxDxH)

Depends on no. of pressure stations, approx. 1300 kgs

There are numerous international standards referring to testing. We supply testing equipment to fulfill any national and international testing standard within our field of business. In case you do not find the standard you are looking for in the below list, please contact us for further information

Standard provides requirements for the manufacture and qualification of spoolable reinforced plastic line pipe in oilfield and energy applications.

Standard test method for time-to-failure of plastic pipe under constant internal pressure.

Standard test method for resistance to short-time hydraulic failure pressure of plastic pipe, tubing, and fittings.

Plastics piping systems - Thermoplastics pipes and fittings for hot and cold water - Test method for the resistance of mounted assemblies to temperature cycling.

Thermoplastics pipes, fittings and assemblies for the conveyance of fluids - Determination of the resistance to internal pressure Part 1: General method, Part 2: Preparation of pipe test pieces, Part 3: Preparation of components, Part 4: Preparation of assemblies.

Standard provides the qualification procedure for type approval of the tightness of hermetically sealed and closed components, joints and parts used in refrigerating systems and heat pumps as described in relevant parts of ISO 5149.

Nonelectrical refrigerant-containing components and accessories, intended for field installation in accordance with the Safety Code for Mechanical Refrigeration, ASHRAE 15.

‘The SCITEQ lab saw is running great. It has cut our sample prep time in half’.

View the full caseYour personal contact with us does not end with the commissioning of your test equipment. We also care about the operation of your solution.

We want to ensure optimal up-time based on preventive maintenance and efficient problem solving. You will achieve higher efficiency, high test reliability and a long life-time on your equipment.

We believe service is the key to a fruitful and long lasting cooperatio

Our services

We give you quality tools to produce as cost-effectively as possible, while meeting the highest standards. You will find it is possible to reduce time-to-market saving time on testing.

We help you configure future proof solutions. The SCITEQ equipment and cloud based software is developed by our in-house R&D engineers and manufactured in Europe.

We are close by. We perform global on-site installation as well as service visits and we are of course available for support and advice daily, so you can rest assured your test equipment will have maximum up-time.

The wide range of SCITEQ standard products is available for very short delivery. We will ship directly to your site to help you meet your deadlines. Need a special version? Not a problem, we love the challange.

We are at your disposal for any questions, comments and suggestions. We look forward to hearing from you.

Feel free to contact us using the contact form below.

We strive to answer all inquiries within 24 hours (on working days).